- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

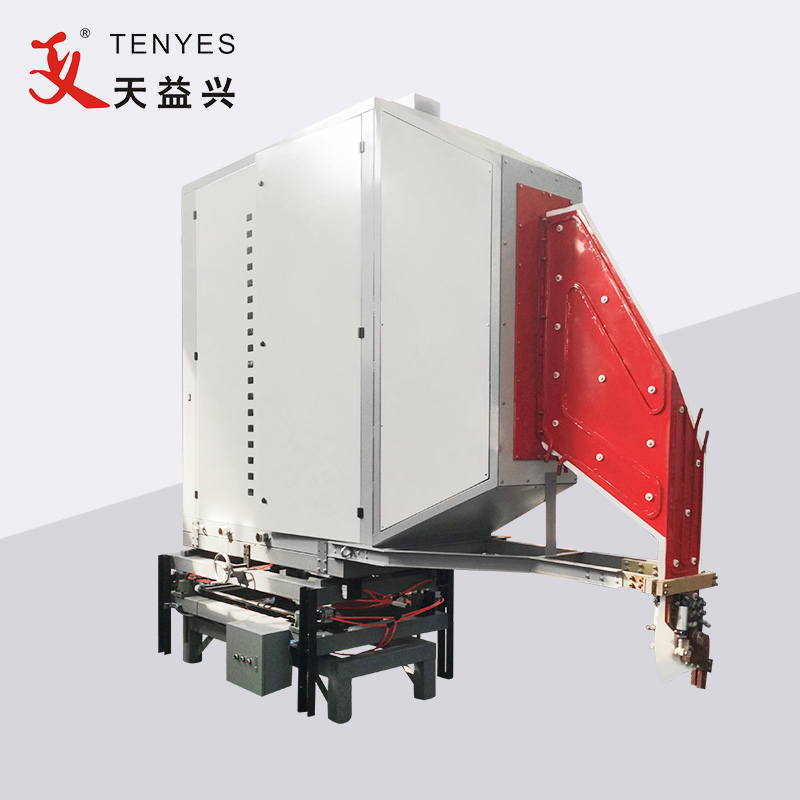

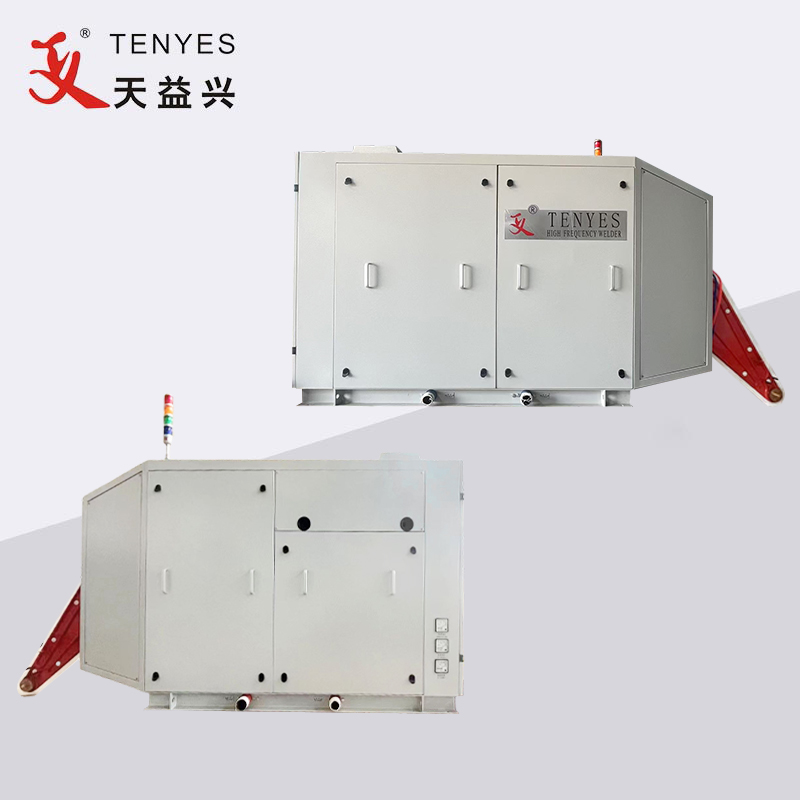

China Solid State High Frequency Straight Seam Welding Machine Manufacturer, Supplier, Factory

With state-of-the-art technologies and facilities, strict high-quality management, reasonable price tag, top-quality service and close co-operation with clients, we're devoted to delivering the top value for our consumers for Solid State High Frequency Straight Seam Welding Machine,Solid State HF Welder,Solid State HF Pipe Welder, To find out more about what we could do for you personally, call us anytime. We look forward to setting up good and long-term company interactions along with you.

Solid State High Frequency Straight Seam Welding Machine, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hot Products

Vacuum Tube High Frequency Induction Heaitng Equipment

TENYES vacuum tube high frequency induction heaitng equipment uses vacuum tube as the important components, single chip microcomputer system as the core forming the intelligent control system have the features of voltage regulating, oscillation and protection.230KW Vacuum Tube Cookware Bottom Brazing Machine

TENYES 230KW Vacuum Tube Cookware Bottom Brazing Machine is a high-tech integrated machine mainly used for brazing composite bottom of stainless steel cookware, such as pots, pans, kettles, and other flat heating surfaces. The machine controlled by multiple sets of microcomputers, making it a sophisticated and advanced equipment that is leading position domestically. The high-precision microcomputer control system of the machine can achieve accurate heating temperature control, ensuring stable and reliable brazing results.160KW Rotary Cookware Bottom Heating Machine

TENYES 160KW Rotary Cookware Bottom Heating Machine has advantages such as Muti-induction heads. Normally other manufacturers adopts three induction heads, but our machine adopts four or five induction heads, so can not only reduce the power burden of each induction head, not easy to burn down, but also make the pot bottom temperature more uniform.1000KW High Frequency Pipe Welding Machine

TENYES 1000KW High frequency pipe welding machine mainly consist of step-down oil transformer,rectifier cabinet,inverter cabinet,console,cooling system,bracket for support inverter cabinet, sometimes also matched with DC driver according to customer’s requirements.Solid State High Frequency Welder AC Driver

TENYES Solid State High Frequency Welder AC Driver mainly used for the dynamic of the tube mill production line, from the steel strip to seam pipe and tube forming and welding and straightening sizing, also can be used for other precision speed adjustment,such as chemical industry and paper making industry etc.300KW SiC-MOSFET Solid State High Frequency Pipe Welder

The 300KW SiC-MOSFET Solid State High Frequency Pipe Welder produced by Tenyes® is mainly used for induction welding of carbon steel welded pipes. It features high temperature and high pressure resistance, a long service life and a low failure rate.