- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

Solid State High Frequency Pipe Welder

TENYES is a large-scale Solid State High Frequency Pipe Welder manufacturer and supplier in China. We have been specialized in manufacturing high & medium frequency and super-audio frequency induction heating equipment. Our products have a good price advantage and cover most of the Southeast Asia, Western Europe, Middle East countries, African countries, West Asia, South America, Russia and so on markets. We look forward to becoming your long-term partner in China.

Send Inquiry

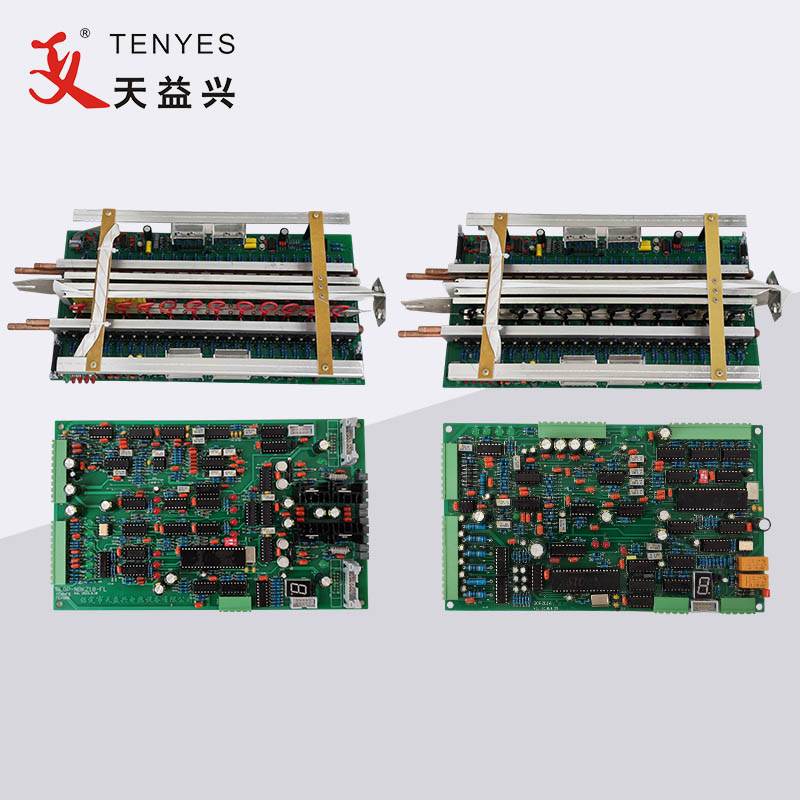

This TENYES Solid State High Frequency Pipe Welder is specially designed for straight seam pipe welding. It adopts high power components of US IR IRFP460 MOSFET and Germany IXYS Company DSEI60-06A rapid recovery diode. The high power capacitor C and inductor coil L compose current-mode parallel upper-voltage resonance circuit, which doesn't need output transformer. Thus, it not only improves the efficiency, but also increases the reliability of the welder.

TENYES Solid State High Frequency Pipe Welder Introduction

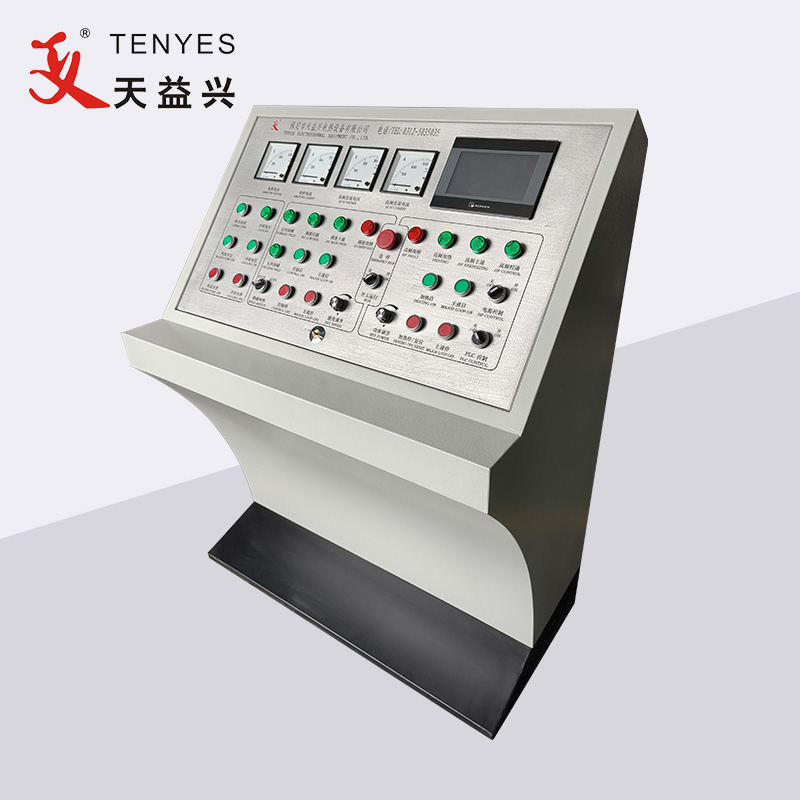

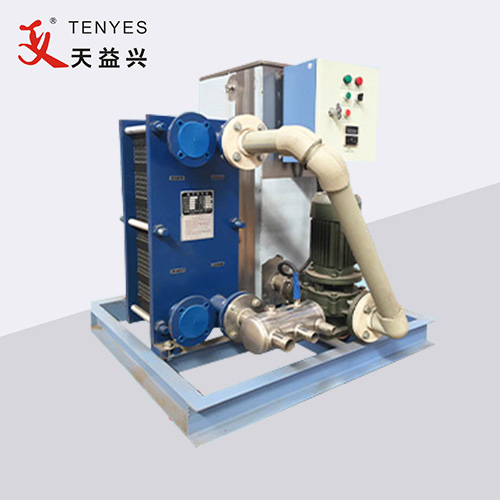

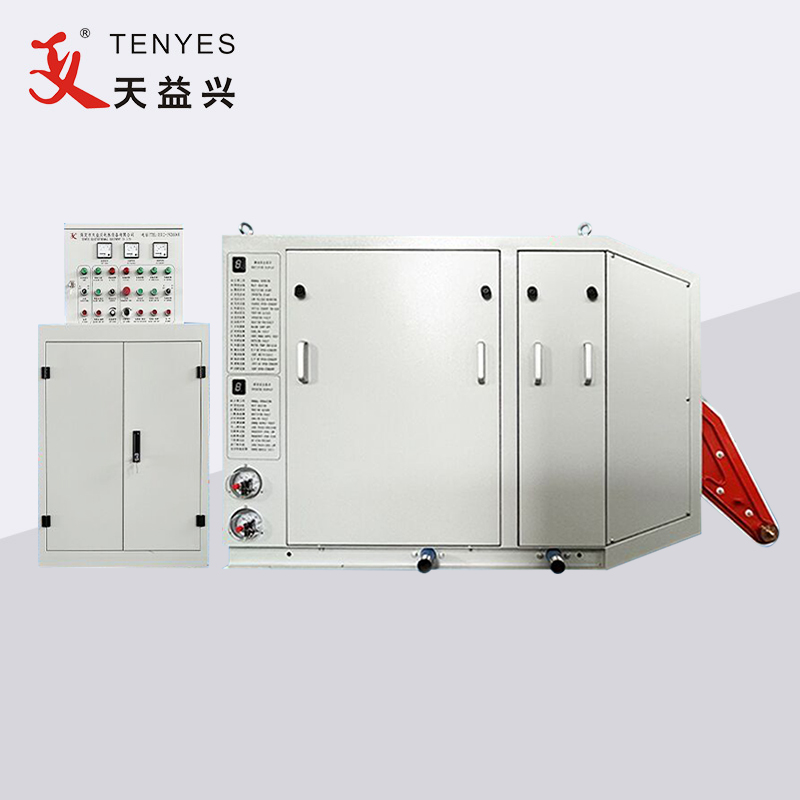

This TENYES Solid State High Frequency Pipe Welder is the most stable pipe welder, and this welder with a 1-year warranty. The TENYES Solid State High Frequency Pipe Welder is mainly consist of rectifying cabinet, inverter cabinet (including air conditioner), console, cooling system and step-down transformer. We adopts tradition SCR rectifying technology. We can manufacture Solid State High Frequency Pipe Welder from 50Kw to 1200KW.

TENYES Solid State High Frequency Pipe Welder Parameter (Specification)

|

Controlled component |

SCR rectifier |

|

Control method |

Phase-shift trigger |

|

Output DC |

Unfilled corner half wave |

|

Stable voltage accuracy |

Less than 5% |

|

Cooling method |

Water cooling |

|

Efficiency AC-DC |

Less than 90%, large reactive power loss |

|

Power factor |

0-0.90 variable, usually 0.75-0.8 |

|

Output voltage tolerance fluctuation range |

±10% |

TENYES Solid State High Frequency Pipe Welder Feature And Application

Welder Scope of application of Solid State High Frequency Pipe Welder:

It is mainly used for welding various types of longitudinal steel pipes such as low carbon steel, high-strength steel, alloy steel, etc.

Solid State High Frequency Pipe Welder features:

1. No high voltage, safe, reliable and efficient.

2. The main components are international famous brand products, such as: IR, IXYS and Siemens, etc.

3. Voltage and current double feedback control circuit, stable regulation, high precision, small interference.

4. The power range is stepless adjustable from 0-100%, with over-voltage, over-current and other fault protection systems.

5. The working status display is digital, the operation is simple, and the maintenance is convenient.

6. The welding quality is good, and the width and heat of the weld are uniform.