- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

Featured Products

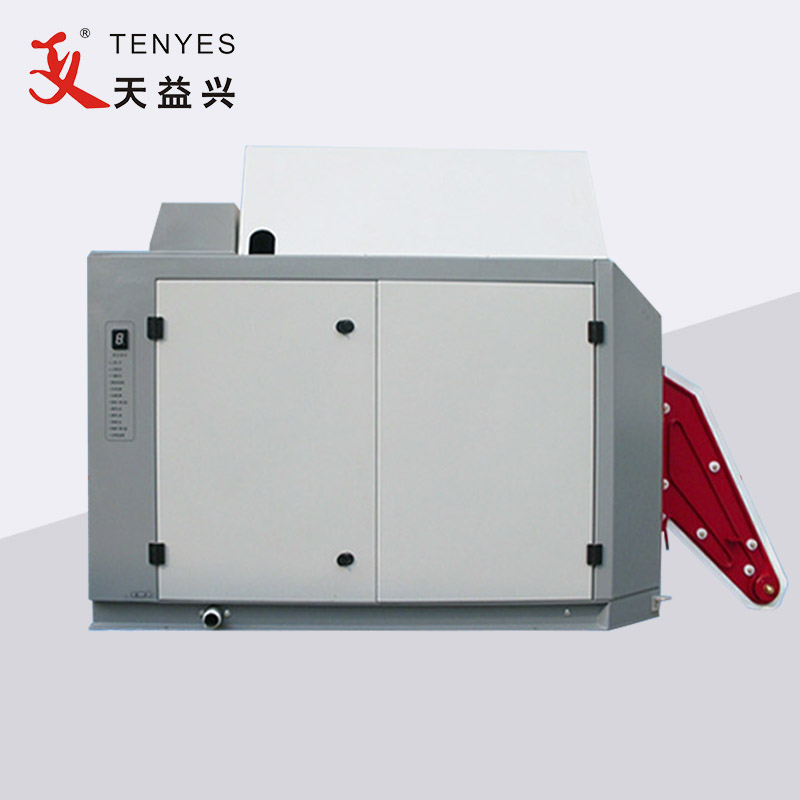

Solid State High Frequency Pipe Welder

Inside Dry Transformer Solid State High Frequency Welder

Solid State High Frequency Contact Pipe Welder

Aluminum Spacer Solid State High Frequency Welder

100KW Transistor Cookware Bottom Brazing Machine

100KW Vacuum Tube Cookware Bottom Brazing Machine

Rotary Cookware Bottom Heating Machine

Straight Cookware Bottom Heating Machine

About Us

Tenyes Electrothermal Equipment Co., Ltd. (former Baoding Tianyi Electrothermal Technology Institute) founded in 1999,and restructured into a company system in 2002.We are a private high-tech enterprise that integrates research and development, production, and technical services. We specialize in producing high and medium frequency induction heating power supplies and supporting equipment, mainly serving the fields of steel pipe manufacturing and metal heat treatment.Main products including Solid State High Frequency Welder,Cookware bottom brazing machine and cookware bottom heating machine,induction heating treatments equipments and so on.