- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

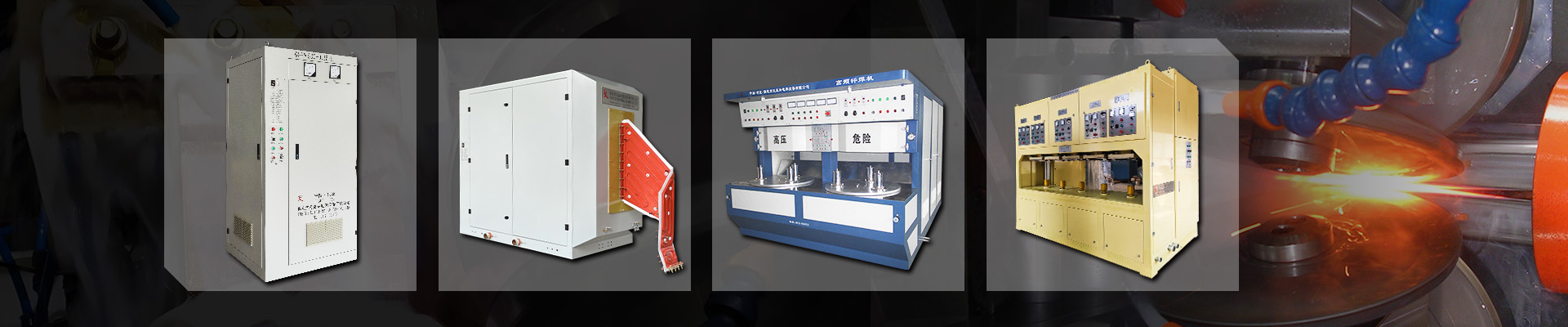

Solid State High Frequency Contact Pipe Welder

2024-11-07

Straight seam pipes contact welding : Usually, induction welding is used in the straight seam pipes production, which put the copper inductor on the needed welding open seam pipes.by using the electromagnetic induction principle,a strong high frequency current surrounding the steel tube is induced inside the pipe.making the edges of the steel strip at the weld to melt and bond together.

However, induction welding is not the only method. In some cases, contact welding can be used, which replacing the inductor with two copper contact heads and directly pressing them on both sides of the weld seam. This allows the welder high-frequency current directly pass to the weld seam edges, melting and bonding both sides edges. Due to the elimination of losses in the process of converting electricity to magnetism and magnetism to electricity, and a shorter current path, losses will be greatly reduced. For large-diameter steel pipes, the energy-saving effect is more significant. This is the main advantage of contact welding.

The main disadvantage of contact welding is the possibility of scratches on both sides of the weld seam, which is not suitable for steel pipes with high requirements.

Above-mentioned all kinds of welders can use the contact welding mode, and only need add 3-Dimension bracket and contact heads.