- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

SERIES TYPE SOLID STATE HIGH FREQUENCY WELDER

I. The working principle is shown in the following figure:

The thyristor rectifier voltage regulation technology is adopted, and there is no input transformer. The inverter bridge adopts high-voltage MOS, and the tank circuit adopts a series resonant structure.

Power range: 30KW~2000KW

Advantages:

1. The inverter bridge loss pulse technology can be used to adjust the load impedance, and the power output is less affected by the load

2. There are more stock equipment in the industry, and there are more maintenance personnel in many places, which is convenient for maintenance

3. There is no input transformer, and the overall weight and volume are small

4. The installation method is also divided into separated welder and compact welder, but the volume is larger than that of parallel circuit, and the material cost is also higher

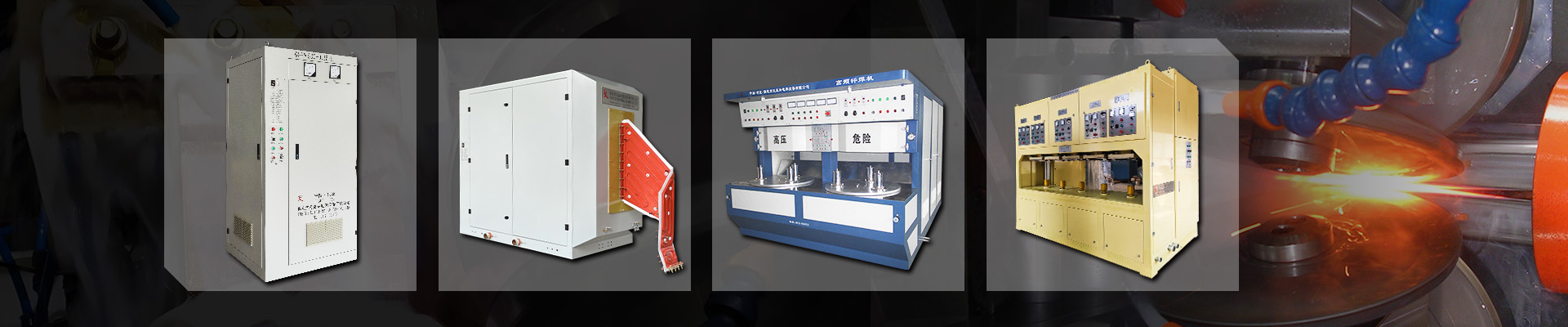

Series separated welder: divided into two cabinets of rectifier and inverter.normally suitable for large power equipment.

Series compact (all-in-one) welder: rectifier and inverter integrated in one cabinet.normally suitable for low power equipment.

II. Series type solid-state high frequency pulse shielding (loss of pulse) principle introduction

The production speed of welded pipes is affected by many factors. The most critical factors are the welder power and pipe wall thickness and diameter. When the pipe shape remains the same, the higher the power, the faster the speed; With the power unchanged, the larger the wall thickness and diameter, the slower the speed. In order to increase speed, it is desirable that the welder will always maintain full power output. The power of the high-frequency welder is equal to the product of the working voltage and current. For a certain size of welder, there is a maximum limit on its working voltage and current (approximately equal to the nominal rating), which cannot be exceeded too much. Any parameter that is too high may cause damage to the welder. Therefore, the voltage and current reach the rated current and rated voltage of the high-frequency welder at the same time, so that the rated power can be output, that is, the maximum allowable power of the welder.

Under normal circumstances, the artificial adjustment of the power of the welder is achieved by adjusting the working voltage, and the magnitude of the working current is determined by the voltage and the impedance of tank circuit. Due to the change of pipe type and the difference of inductor, magnetic rod, and opening angle, the impedance of tank circuit (capacitance and inductor) is different. Therefore, it is difficult to achieve the best match between the voltage and current of the high-frequency welder (and at the same time achieve the rating), and it is also difficult to achieve the maximum power.

In order to solve this problem, a high-frequency power supply with series resonance can be used to adjust the current by adjusting the inverter pulse. Normally, the two pulses that drive the inverter MOS are inverting and continuous, when there are pulses, the MOS is turned on and the inverter bridge has a current output.When there is no pulse, the MOS is turned off, and the inverter bridge does not output current. In this way, if one pulse is blocked every few pulses, a part of the current can be blocked, and the average current will be reduced, which is equivalent to an increase in the impedance of the tank circuit, so that it is possible to achieve the best match between voltage and current.

When the maximum power output of the high-frequency welder is not required, the current can be reduced by reducing the pulse, increasing the impedance, and only making the voltage reach the rated value. This high and low voltage low current working mode can improve the power factor of the high-frequency welder, reduce reactive power loss and harmonic interference.

The high-frequency welder with pulse shielding technology only requires the replacement of the inverter control board and certain external components, with little change in structure and appearance. It also has no effect on high-frequency.

However, due to the discontinuous pulse, the current is unstable, which may put pressure on components such as filtering capacitors.