- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

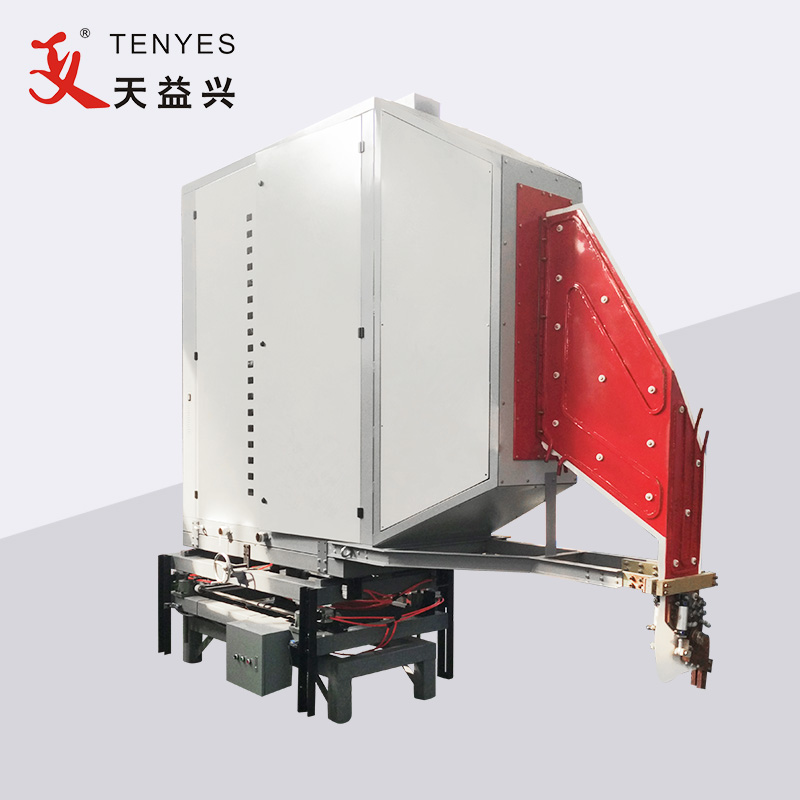

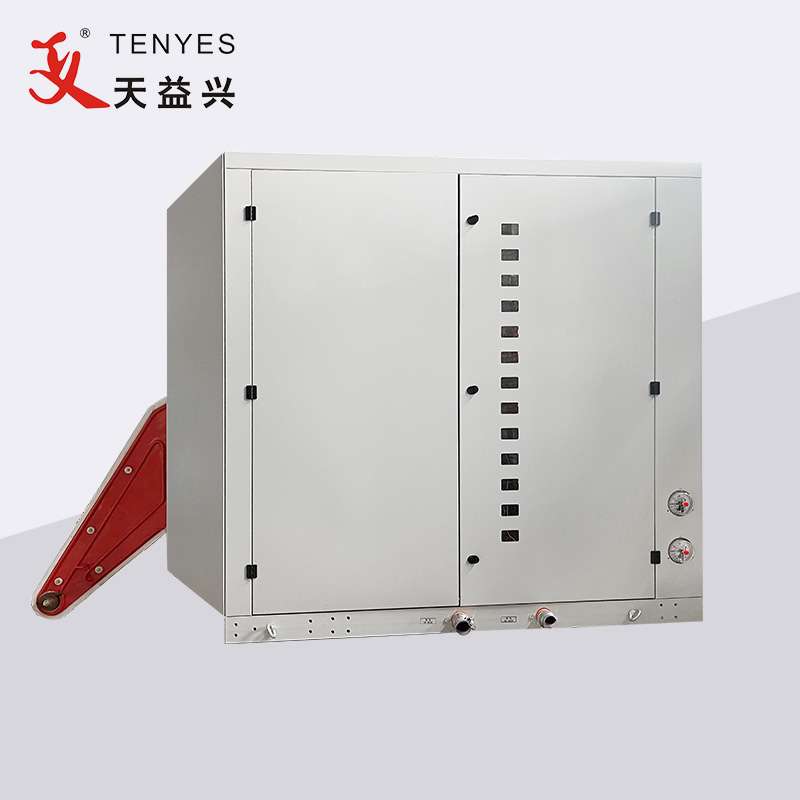

800KW High Frequency Pipe Welding Machine

TENYES 800KW High frequency pipe welding machine mainly consist of step-down oil transformer, rectifier cabinet, inverter cabinet, console, cooling system, bracket for support inverter cabinet, sometimes also matched with DC driver according to customer's requirements.

Send Inquiry

TENYES 800KW High frequency pipe welding machine ordinary three-phase AC power (line voltage 380V, frequency 50HZ) is reduced by a transformer (line voltage 200V, frequency 50HZ), enters the rectifier cabinet, undergoes rectification, voltage regulation, and filtering, and becomes continuously adjustable DC power from 0 to 240V; Entering the inverter bridge again (using high-power transistor MOSFET), it becomes high-frequency current, which can be supplied to the load slot for induction heating. The inverter slot power unit adopts a modular structure, and each pair of power units can output a power of over 50KW. The number of power units used varies depending on the power of the equipment, and the basic structure of the equipment is the same regardless of its size. The slot is a series parallel hybrid resonant form, without high voltage and output transformer. The number of power units used in this device is sixteen pairs.

TENYES 800KW High frequency pipe welding machine Parameter (Specification)

|

Application |

Operation parameter |

Power supply |

|||

|

Steel pipe OD |

Φ165-Φ508 |

Rated power |

800kW |

Power supply form |

3AC380 ±5% |

|

Steel strip thickness |

3.0-10.0 |

Rated DC voltage |

240V |

||

|

Welding mode |

Induction or contact type |

Rated DC current |

4000A |

Power distribution capacity |

Larger than1000KVA |

|

Rated frequency |

200KHZ |

Power factor |

≥0.85 |

||

|

Welding speed |

10-20(m) |

Efficiency |

≥85% |

Power supply cable |

Each phase of plastic-covered copper wire≥800mm² Ground wire ≥400mm² |