- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

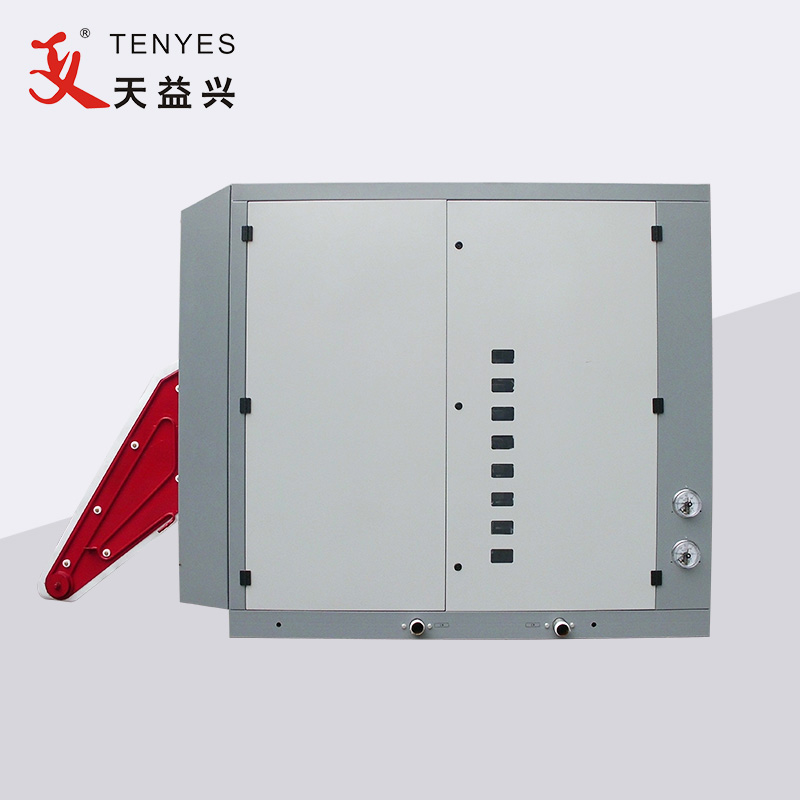

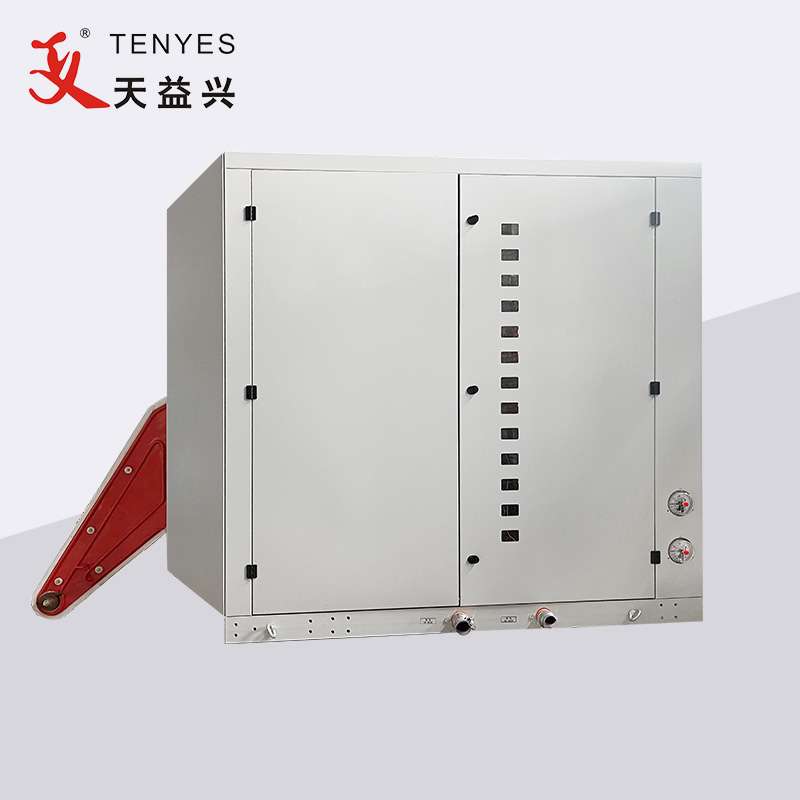

400KW High Frequency Pipe Welding Machine

The 400KW High frequency pipe welding machine is designed for straight seam inductive welding of steel pipe. The whole set consist of rectifying cabinet, inverter cabinet, circulating cooling system for soft water, step down transformer, console, and so on.

Send Inquiry

Compared to vacuum tube power supply, the solid state high-frequency power source contains high scientific and technological content with closely combine strong and weak electricity in the circuit. Effects brought by structural configuration can also not be ignored. However, that does not mean it is difficult to maintain solid state high frequency power supply. Also it can't illustrate the maintenance of solid-state power source is in need of very advanced knowledge and experience. On the contrary, because of designers' full consideration of these problems at the early stage of designing, they on one hand improve the reliability and stability of supply power as a whole so as to reduce the possibility of failure or achieve no failure; On the other hand, trying harder in convenient retrieval and finding traces even if the Equipment is out of order, user's maintenance staff can also take a quickly find out the cause of the problem, treating symptomatically. According to the actual situation on sites, the design of primary cabinet is sealed box structure to prevent apparatus from the effect of dust on-sites. Here are some obvious features of the third generation of solid state high frequency power supply.

TENYES 400KW High frequency pipe welding machine Parameter (Specification)

Rated Output power: 400kW

Welding mode: induction type

Rated DC voltage: 240V

Rated DC current: 2000A

Rated frequency: 250KHZ

The whole efficiency: η≥85%

Power supply voltage: 3-phase 380V/50Hz (equipment could work at the voltage 380V±5%)

Power distribution capacity: ≥500kVA

Power factor: ≥0.85

Power supply cable: each phase of plastic-covered copper cable ≥400mm², ground wire≥200mm2

Supply list

|

Description |

Composition / Model |

Qty. |

|

400KW High frequency pipe welding machine |

Rectifier cabinet |

1 |

|

Inverter cabinet |

1 |

|

|

Air conditioner |

1 |

|

|

console |

1 |

|

|

Transformer |

1 |

|

|

Water-water cooling system |

1 |

|

|

2-dimension bracket |

1 |

TENYES 400KW High frequency pipe welding machine Feature And Application

1. The simple circuit and convenient installation

2. Complete protection and easy maintenance

3. Small harmonic interference and no pollution to power grid

4. Safe without high pressure and no fire striking to steel pipe by the induction coil

5. High efficiency, obvious energy-saving, less of cooling water

6. Less spattering and good quality of welding