- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

China High Frequency Pipe Welding Machine Manufacturer, Supplier, Factory

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for High Frequency Pipe Welding Machine,Solid State High Frequency Welder,Solid State High Frequency Compact Pipe Welder, Welcome to speak to us should you be intrigued inside our solution, we're going to provide you with a surprice for Qulity and Price tag.

High Frequency Pipe Welding Machine, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our objects, remember to feel free to contact us for quotation and product details.

Hot Products

Aluminum Spacer Solid State High Frequency Welder

Aluminum Spacer Solid State High Frequency Welder is mainly designed for welding aluminum spacer or automobile warm edge strips. TENYES company is from China have been specialized in induction heating for many years. Many countries have imported our equipment such as South Asia, Southeast Asia, South America and so on.Solid State High Frequency Welder DC Driver

TENYES Solid State High Frequency Welder DC Driver is mainly used for the control of Direct current motor of Tube mill production line. It can achieve multiple motors linkage,so if customer choose this DC driver need first make sure how many motors of their tube mill production line needs.Cookware Bottom Electric Screw Press Equipment

Cookware bottom electric screw press equipment is a precision forging equipment. It can form the forming process, adjust the striking force and combat powers base on the forging. Using switched reluctance drive, it has a low starting current, high starting torque, and good speed performance. It is mainly used for hardware tools, medical equipment, utensils and other metal forging and stainless steel clad bottom pot pressure welding process.Tube Seam Online Annealer

TENYES company not only produce high frequency equipment and also produce medium frequency equipment, such as Tube Seam Online Annealer, we also one manufacture and supplier in China of this kind of equipment. We have rich experience in producing medium frequency equipment. Recently we export Annealer to south Korea country and before also many other countries.150KW Solid State High Frequency Compact Pipe Welder

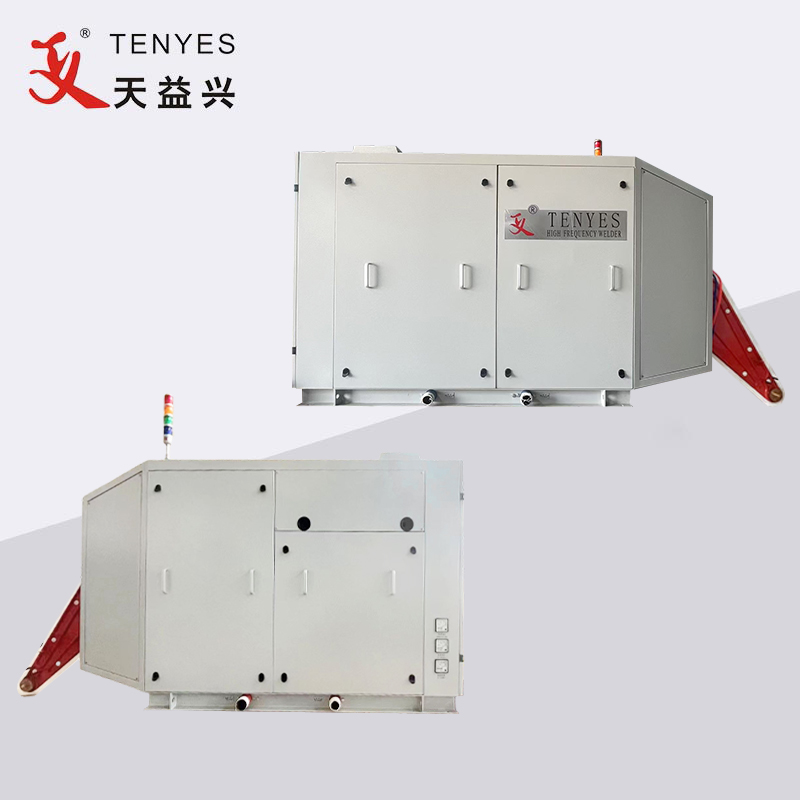

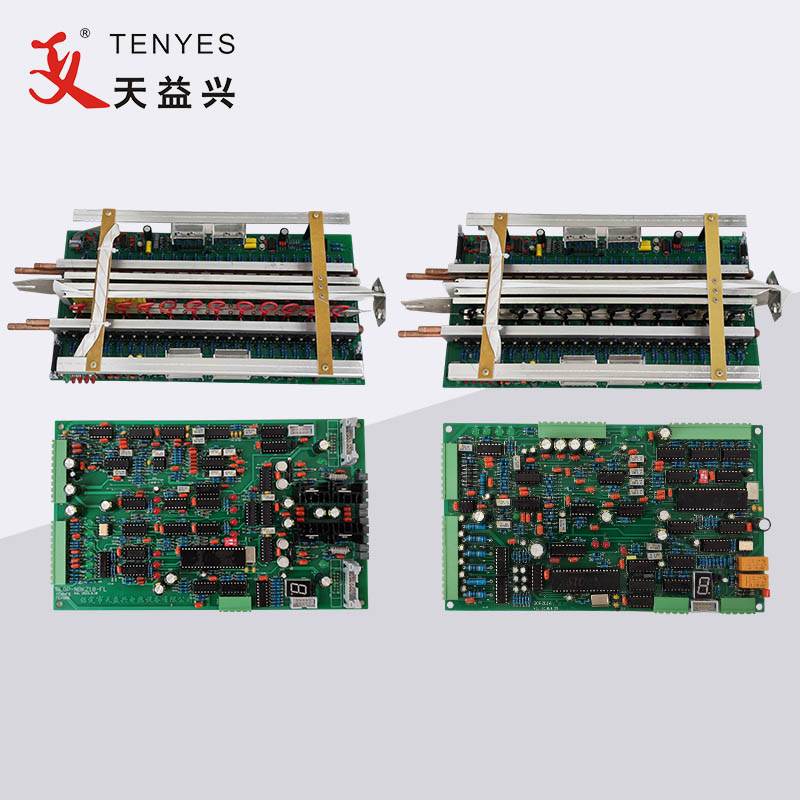

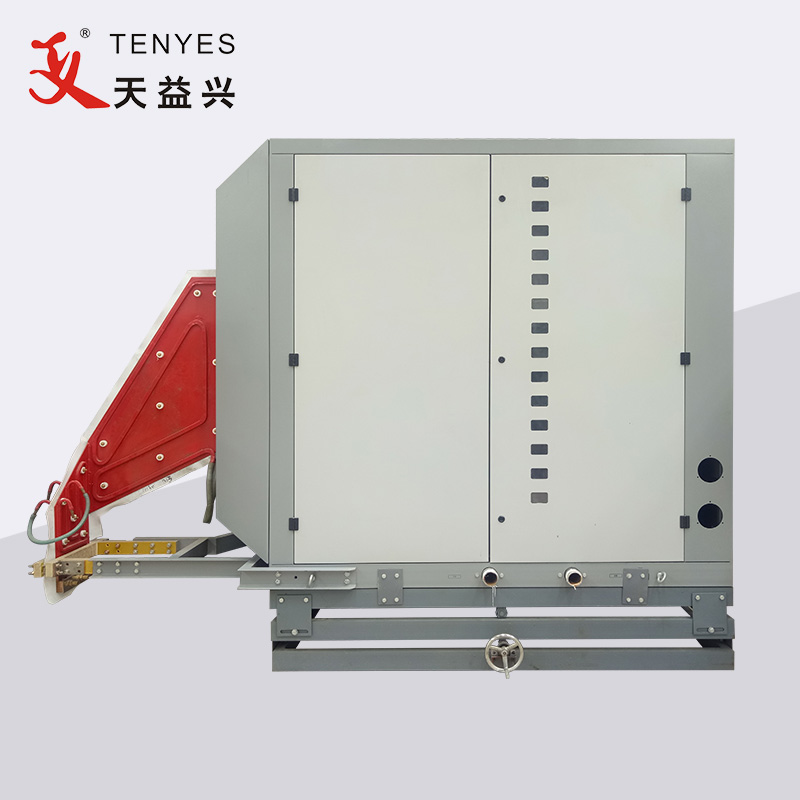

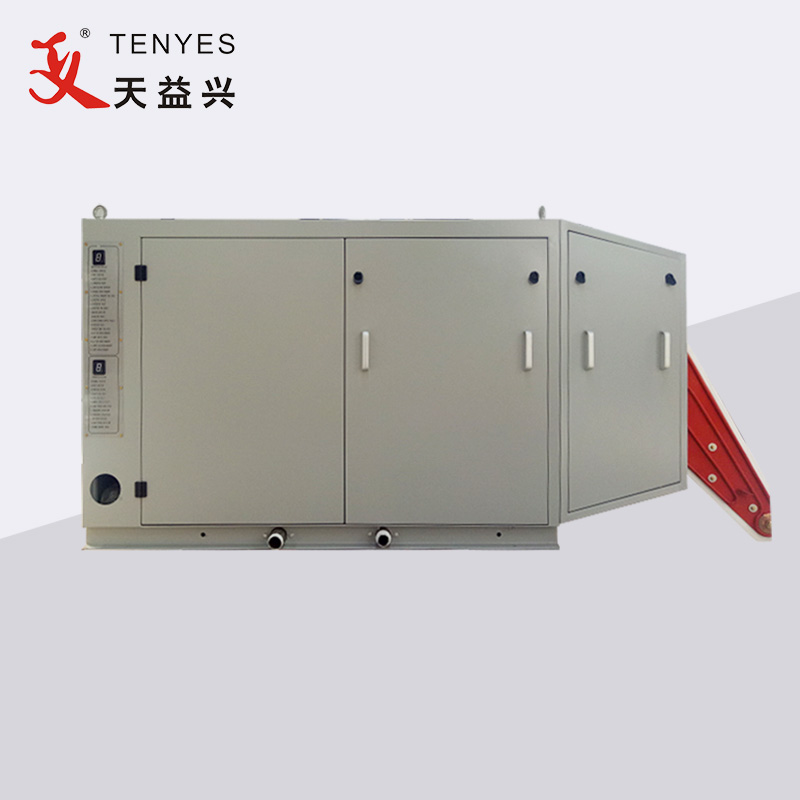

The existing solid-state high-frequency products in China are basically similar, mainly including rectifier, inverter and output. Now our 150KW Solid State High Frequency Compact Pipe Welder is widely used in the welding of steel pipe and aluminum strip. The rectifier part is mainly a three-phase full bridge rectifier circuit composed of six thyristors.200KW Solid State High Frequency Compact Pipe Welder

As known in China, TENYES is a trusted partner for businesses and seeking reliable, efficient, and high-quality welding equipment. With rich experience and expertise, TENYES has established itself as a leading manufacturer and supplier of welding equipment, including 200KW Solid State High Frequency Compact Pipe Welder and catering to the needs of clients both domestic and overseas. The 200KW Solid State High Frequency Compact Pipe Welder is energy efficient and eco-friendly, with power savings of over 5% when compared to conventional high-frequency welder, thanks to its high power factor of up to 0.94. Its shorter connecting cables and without a step-down transformer enable this welder to conserve energy while reducing the cable losses.