- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

What Makes a Solid State High Frequency Welder the Smart Choice for Modern Pipe Production?

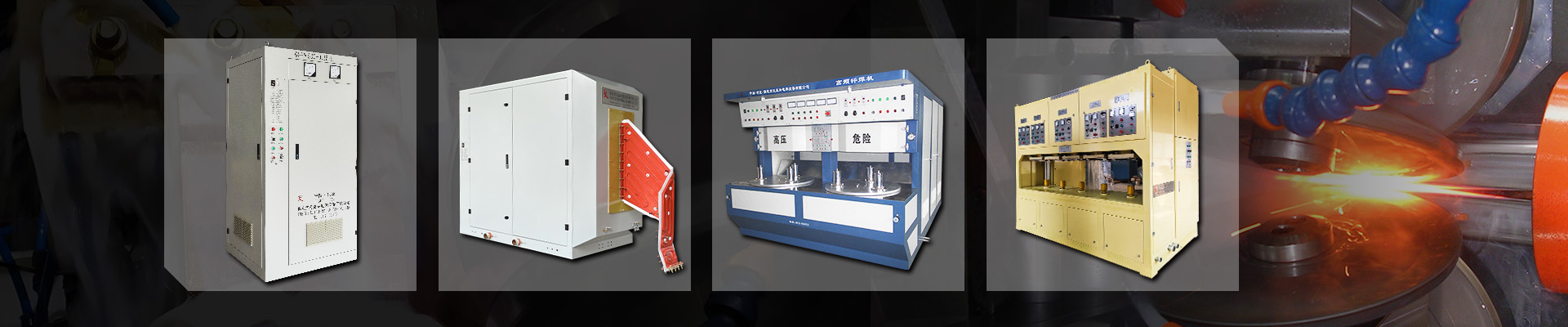

In today's highly competitive manufacturing industry, solid-state high-frequency welder technology is revolutionizing the way industries produce robust and reliable steel pipes, eliminating the risks associated with complex and high-pressure traditional systems. Numerous manufacturers worldwide are upgrading to this precise, efficient, and safe welding technology for the following reasons. Let's delve into why TENYES, a leading manufacturer and supplier in China, has set a new benchmark for seamless welding performance with its welding equipment.

Advantages of Solid State High Frequency Welders:

Traditional welding methods are often inefficient, produce inconsistent quality, and are energy-intensive. Therefore, solid state high frequency welders, specifically designed for high-speed, high-precision longitudinal seam welding of pipelines, have emerged. Their core advantage lies in using solid-state electronics to generate controllable high-frequency current. This is not just an upgrade, but a revolution, bringing tangible benefits:

1. Consistent Stability and Superior Quality: Precise heating achieves superior weld penetration, avoiding excessive deformation or the "heat-affected zone" problem that plagues other welding techniques. This means stronger pipes that reliably pass stringent inspection standards.

2. Significant Energy Savings: Compared to outdated vacuum tube systems, solid-state technology itself significantly reduces electrical energy loss as heat.

3. Ease of Use: Solid-state systems are inherently more reliable and require less maintenance. A clear digital control interface makes operation and troubleshooting easier. TENYES offers a one-year reliability warranty.

4. Safety First: Using lower input voltage and eliminating dangerous high-voltage klystrons significantly reduces the risk of electric shock, creating a safer working environment for your employees. 5. Protects your materials: Concentrated and rapid heating minimizes deformation and metallurgical damage, thus maintaining the inherent strength of the steel pipe.

6. Flexible and convenient: Power output adjustment is quick and easy, minimizing changeover time and reducing waste.

TENYES Solid State HF Welder Core Performance And Protection

| Feature | TENYES Advantage | Why It Matters for Your Production |

|---|---|---|

| Core Tech | Advanced Solid State IGBT/Mosfet (IR, IXYS, Siemens) | Reliability: Less breakdowns, minimal downtime. Efficiency: Lower energy use. Precision: Superior control over the weld heat. |

| Control System | Voltage AND Current Double Feedback Loop | Consistency: Rock-solid power regulation, immune to line variations. Produces uniform, high-quality welds every time. |

| Power Range | True Stepless Adjustment (0% to 100% Power Output) | Ultimate Flexibility: Smoothly adapt to any pipe thickness, material, or speed requirement without limitations. |

| Protection | Automated Systems (Over-Voltage, Over-Current, Over-Temperature) | Investment Protection: Safeguards critical components against unexpected failures, extending machine life. |

| Interface | Intuitive Digital Display & Simple Controls | Operational Ease: Quick training, straightforward operation, easy troubleshooting. |

| Safety | Designed for Low Operating Voltage, No High-Voltage Tubes | Reduced Risk: Creates a significantly safer working environment for personnel. |

Typical TENYES Solid State HF Welder Capability Range

| Machine Power Rating | Typical Pipe Applications | Core Strength |

|---|---|---|

| 50KW - 150KW | Smaller diameter pipes, light gauge materials (e.g., furniture, conduit) | Precision & Speed: Ideal for high-volume, small size production. |

| 200KW - 500KW | Medium diameter pipes, standard structural applications | Versatility & Robustness: Handles the bulk of common pipe production needs reliably. |

| 600KW - 1200KW | Large diameter pipes, thick walls, high-strength steels | Industrial Muscle: Tackles the toughest projects requiring deep penetration and high heat on demanding materials. |

Why the World Chooses TENYES Solid State High Frequency Welders

Beyond its impressive specifications and features, the success of TENYES solid-state high-frequency welders speaks for itself. Our equipment is not only popular in China but also highly regarded globally. TENYES welders operate reliably on critical pipeline production lines in the following regions:

Southeast Asia: Supporting infrastructure construction.

Western Europe: Meeting stringent quality requirements.

Middle East and West Asia: Supporting the booming oil, gas, and construction industries.

Africa: Supporting key water and energy projects.

South America and Russia: Driving the development of the resource extraction and processing industries.

This broad global reach is no accident; it stems from the tangible value TENYES creates for its customers: superior weld quality, excellent operational stability (reducing costly downtime to below 0.5%), faster production speeds, significant energy savings, and enhanced workplace safety. A one-year warranty further underscores TENYES' commitment to product reliability.

TENYES' solid-state high-frequency welder is more than just a tool; it's a strategic asset that delivers measurable results to your plant: superior weld integrity, lower operating costs, consistent output, and the safety and reliability your team needs—all under control. Ready to boost the efficiency, consistency, and profitability of your pipeline production? Explore the proven, globally trusted performance of TENYES' solid-state high-frequency welder—the perfect choice for modern, intelligent, seamless pipeline production that meets today's demands.