- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

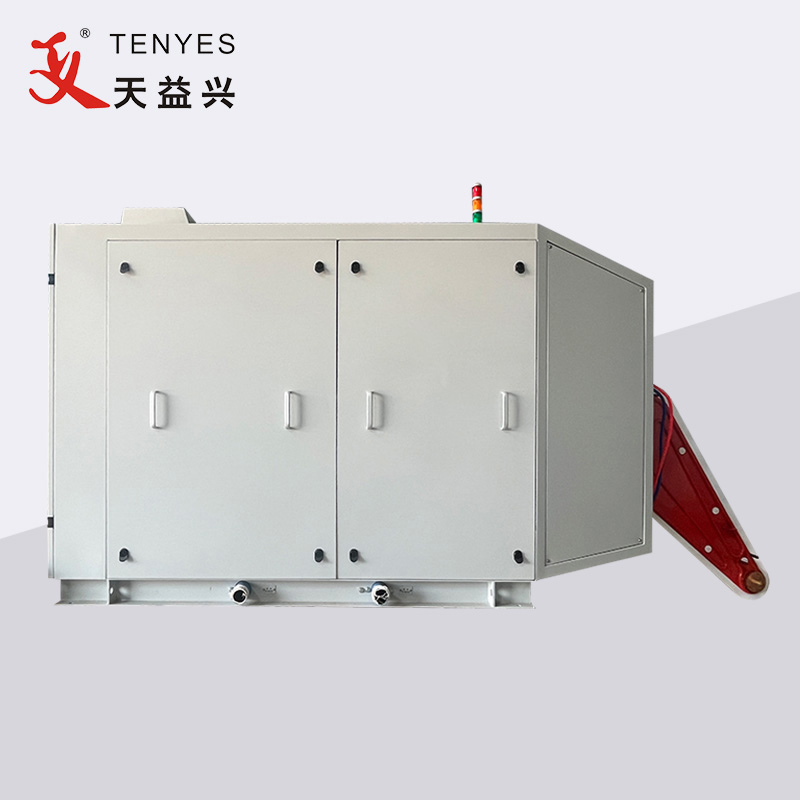

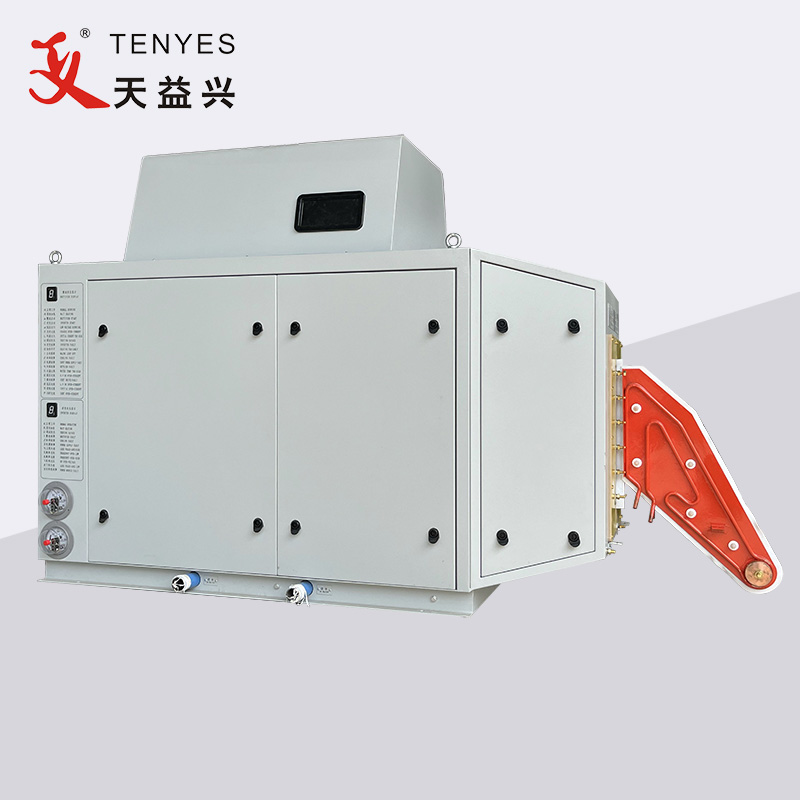

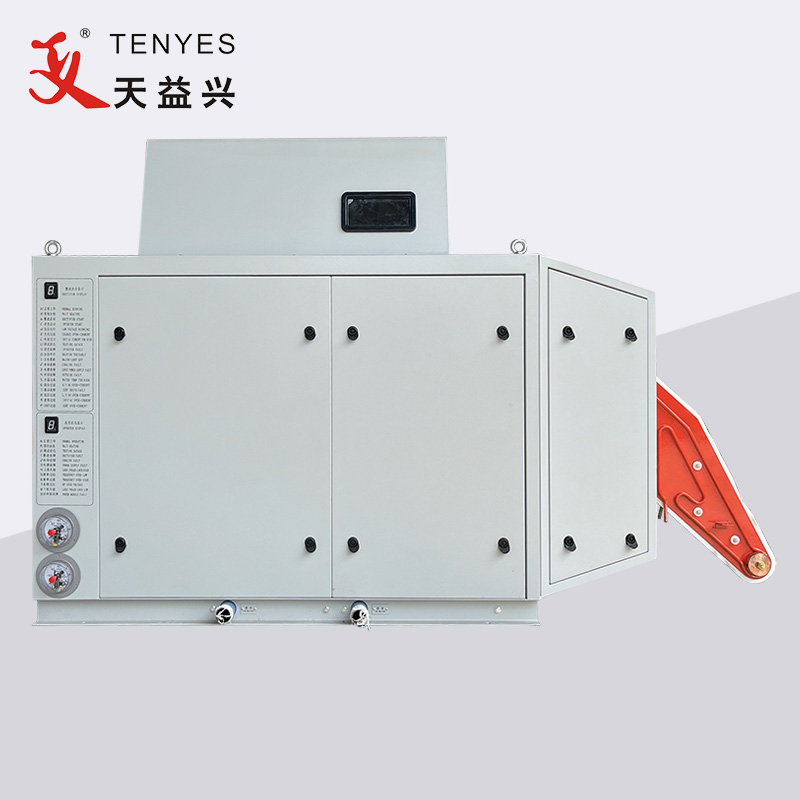

New Structure Solid State HF Compact Pipe Welder

TENYES® new structure solid state HF compact pipe welder is developed by our engineers.The main cabinet integrated rectifier and inverter function, and the internal structure adopts an integrated and compact welding machine design scheme. After rigorous mechanical analysis and thermal simulation verification, the overall structure becomes more scientific and reasonable.

Send Inquiry

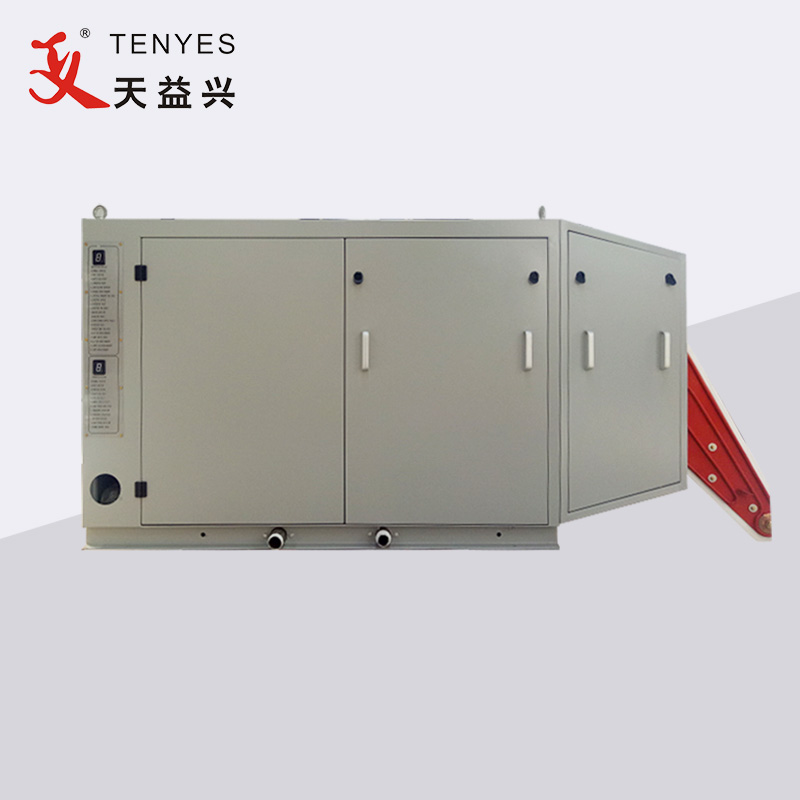

Instead of traditional separate-type layout of rectifier cabinets and inverter cabinets, this new structure solid state HF compact pipe welder integrates the two core functional units into a single compact cabinet. This integration not only reduces the overall equipment footprint by simplifying the system structure but also shortens the internal wiring distance between the two units, minimizing signal interference and improving the stability of power transmission during the welded pipe production process.

Solid State HF Compact Pipe Welder normally consists of the following parts:

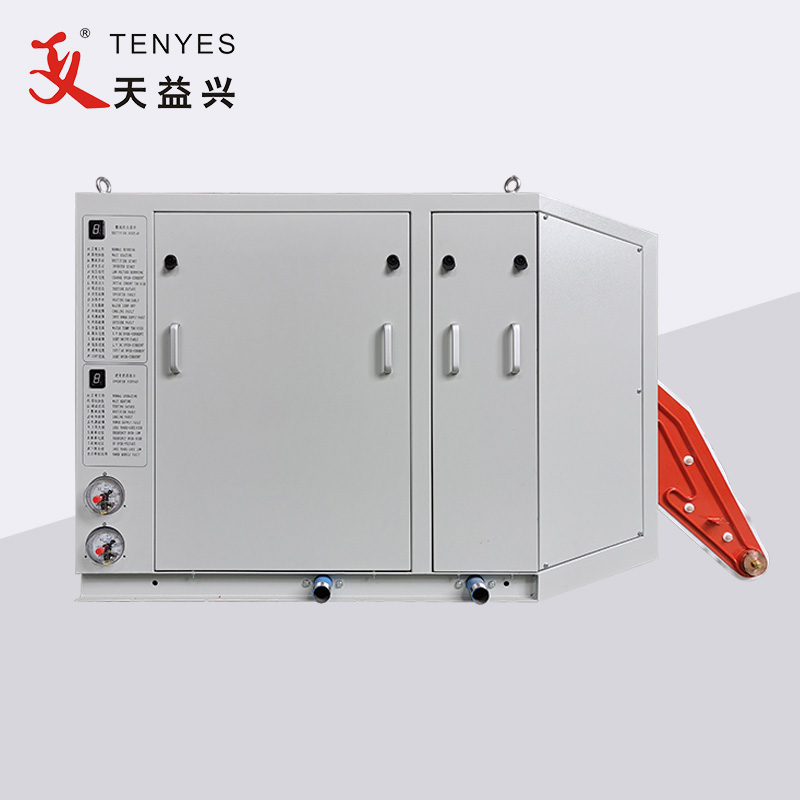

1.New structure Solid State HF Compact Pipe Welder Main cabinet:

We use this new structure which make rectifier and inverter cabinet all in one cabinet.This new design can save more space and easy for customer connect cables.For this new structure now we design from 50Kw to 400Kw. If more larger power welder we still suggest use separately kind of pipe welder.

2.Dry Transformer Cabinet

Inside this Dry transformer cabinet we equipped with an dry step-down transformer,which can instead of traditional oil transformer,can easily finish the shipping delivery to many countries.

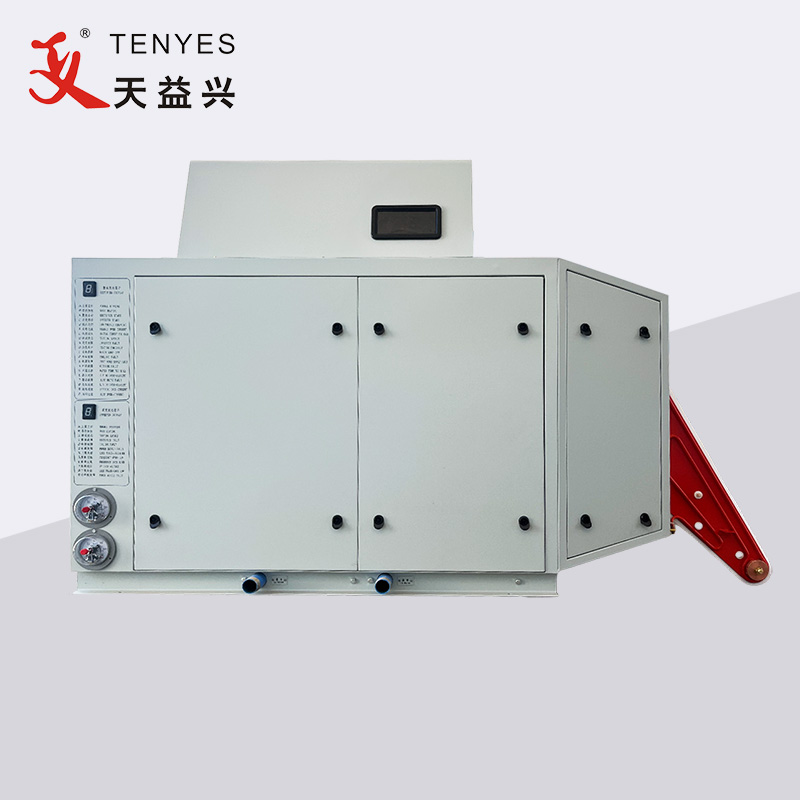

3.Console

Central control console can achieved remote operation of solid state HF compact pipe welder,speed control cabinet(driver),water cooler,fans etc. Equipment.

4.cooling systems: water-water cooling system or air-water cooling system optional

The cooling system of the new structure solid state HF compact pipe welder is mainly used for internal circulation closed-circuit cooling of high-frequency welder and water-cooled speed control cabinets(driver). Normally have two kinds:air-water cooling system and water-water cooling system. The air-water cooling system can work independently, and the water-water cooling system needs to be equipped with a cooling tower or pool. This equipment occupies a small area, and the inlet water temperature of the heating power supply is effectively controlled below 40° C to ensure the long-term stability of the heating equipment.