- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

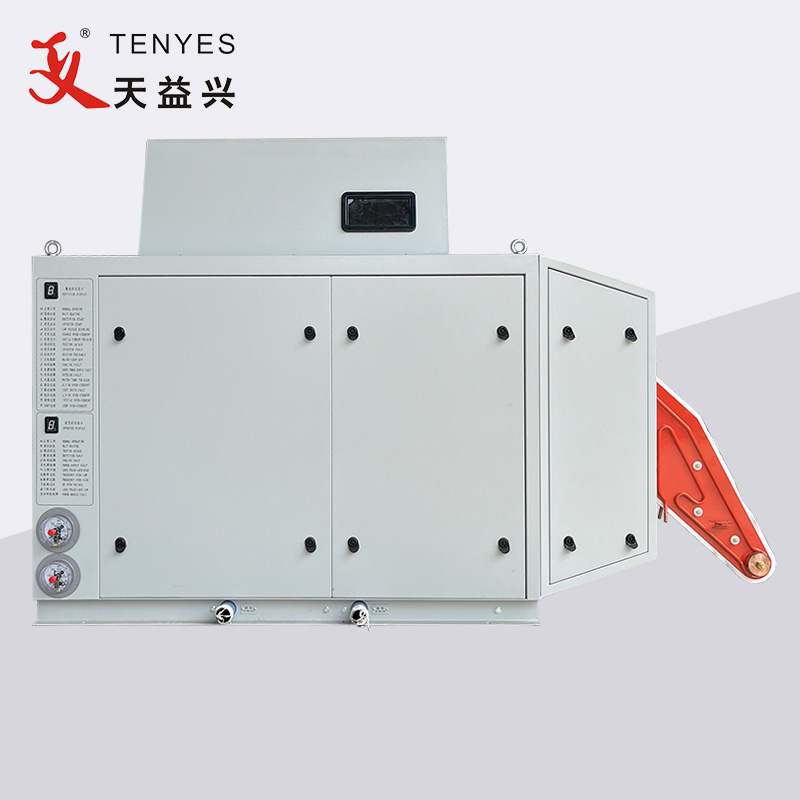

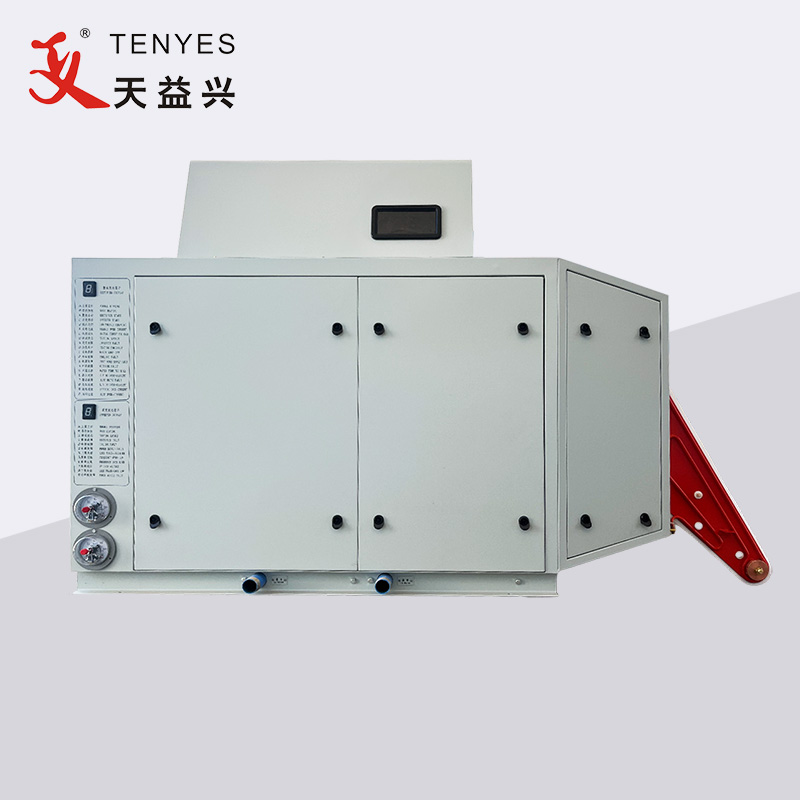

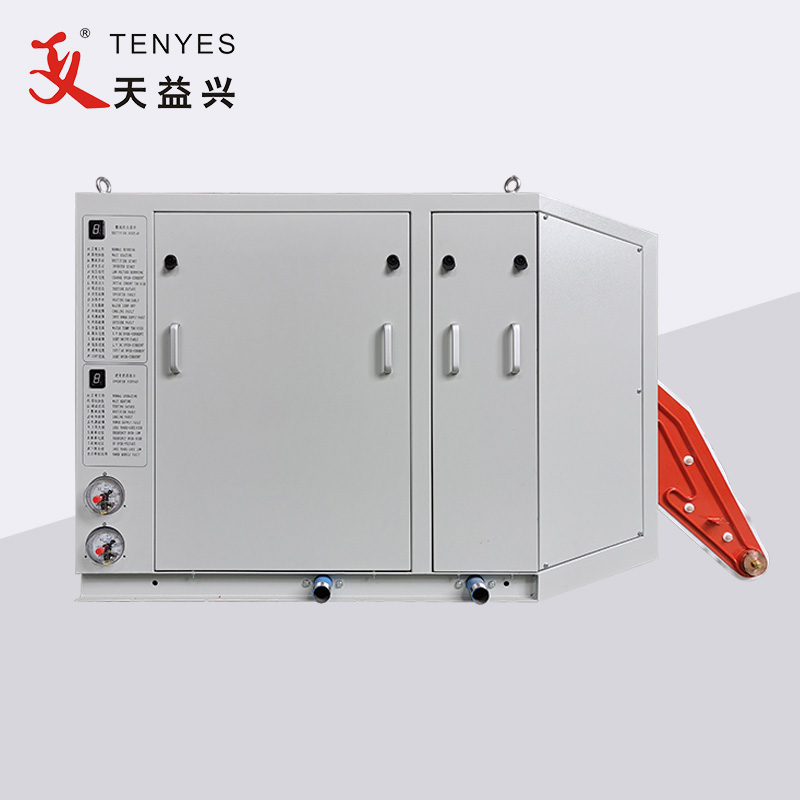

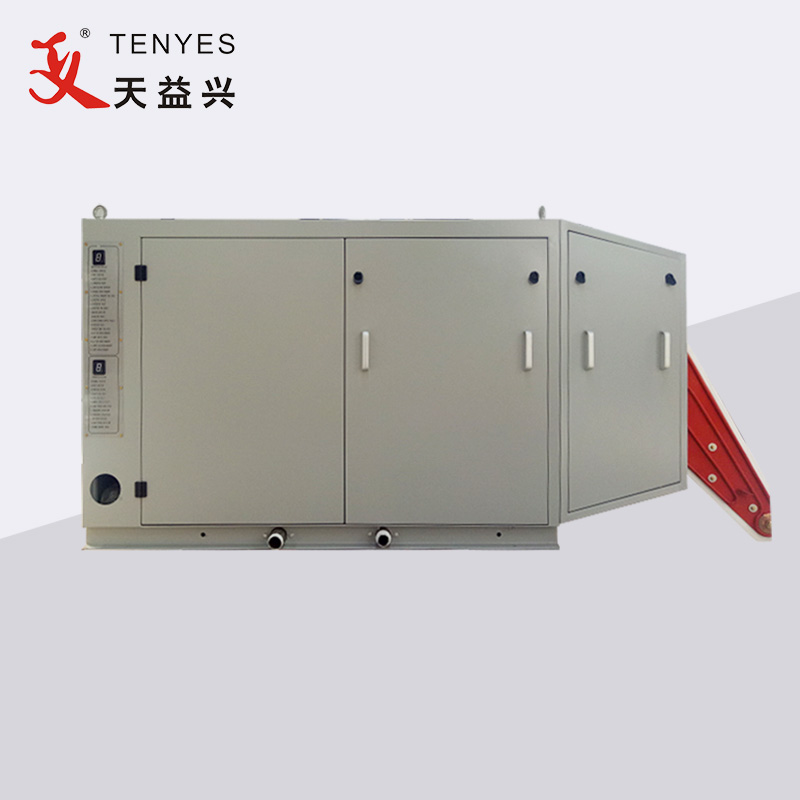

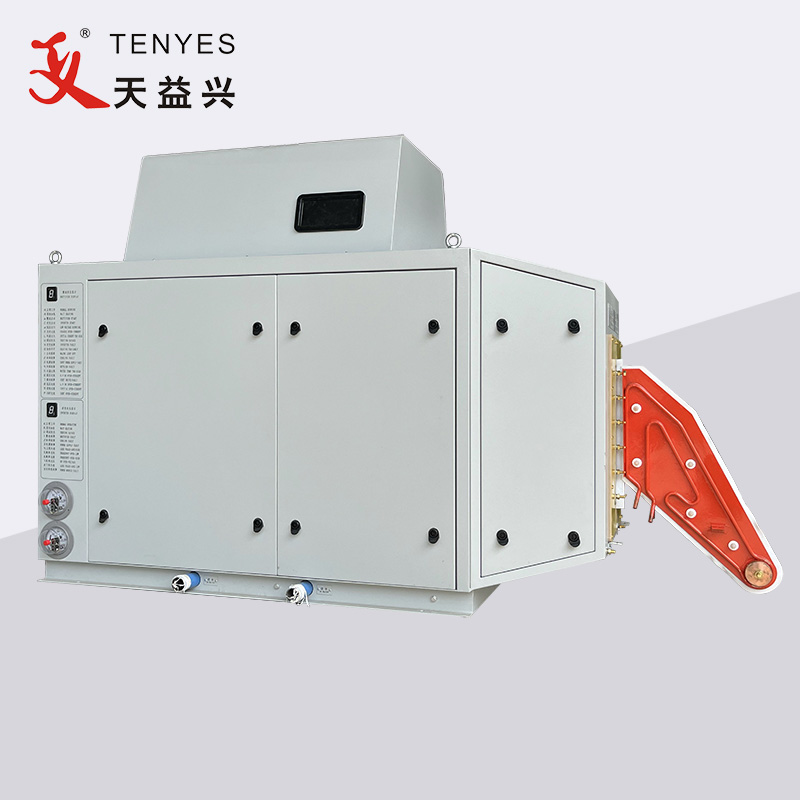

300KW Solid State High Frequency Compact Pipe Welder

TENYES is a highly reputable Chinese company with a well-established reputation for manufacturing solid state high frequency pipe welding equipment, including the 300KW Solid State High-Frequency Compact Pipe Welder. TENYES 300KW Solid State High Frequency Compact Pipe Welder is an advanced design, technological features, reliable welding equipment. The 300KW Solid State High Frequency Compact Pipe Welder adopts Digital control rectifier cabinet and adopts PWM switching power supply to increase the power factor of the welder, and the DC uses flat wave reactance as a filter to meet the working requirements of the inverter in order to reduce the output voltage ripple of the welder and improve the wave coefficient index.

Send Inquiry

Technical Parameters

|

Model |

GGP300-0.3-H |

|

Application |

Welding carbon steel, galvanized steel strip, stainless iron, aluminum and other materials, wall thickness range of 0.5-1.5 mm. Welding (round pipe, square pipe, special-shaped pipe, composite pipe), etc. Welding speed is 60-130 meters per minute. |

|

Rough size |

2435mm*900mm*1800mm(L*W*H) |

|

Welding mode |

induction type |

|

RatedOutput power |

300kW |

|

Rated DC voltage |

240V |

|

Rated DC current |

1500A |

|

Rated frequency |

300KHZ |

|

The whole efficiency |

η≥90% |

|

Ripple factor |

<1% |

|

Power distribution capacity |

≥360kVA |

|

Power factor |

≥0.96 |

|

Power supply voltage |

3-phase 380V/50Hz (equipment could work at the voltage 380V±5%) |

Brief introduction and advantages of 300KW Solid State High Frequency Compact Pipe Welder

Dear customers, thank you for choosing our equipment. We will do our utmost to cooperate with you in good faith, to make our equipment and after-sales service work well, to make the best performance and create the maximum benefit for you.

To avoid unnecessary losses, now we would like to describe more details about the requirements for the installation and use of the equipment and the problems to be noted.

This equipment is a high-tech machine, and was carefully developed by our company's engineers on the basis of our company's common solid-state high frequency. Also this welder used in the field of straight seam welded pipe (induction welding, contact welding), hardening, brazing and so on. Compared with the original and normal solid-state high-frequency equipment, it has the following advantages:

1.Small size and light weight: The rectification part and the inverter part are installed in one cabinet. The installation is compact and reasonable. The overall volume is 50% smaller than the ordinary high-frequency equipment of the same specification, and the weight is reduced by more than 30%.

2. Energy saving and water saving: without the step-down transformer, the interconnection cables are obviously shortened, and the power factor is as high as 0.95, thus reducing many line or cables losses. Tests have shown that this equipment can save more than 5% of electricity than ordinary solid-state high-frequency equipment of the same specification.

3. The rectifier part adopts the diode uncontrollable rectifier bridge, so there is no need to recognize the phase, and the three-phase power supply ABC is connected freely, which is convenient for testing and maintenance.

Main circuit description

The main circuit of this device is basically the same as the thyristor intermediate frequency power supply (see attached figure). The three-phase 380V AC enters the three-phase full-control bridge and becomes a pulsating DC. The smoothing reactor and the filtering device convert this DC filter into a straight DC, and then become a high-frequency AC supply tank through the single-phase inverter bridge. The circuit (the capacitor and the inductor form a tank) acts as an oscillating power source.

The following is the electrical schematic of the device: