- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

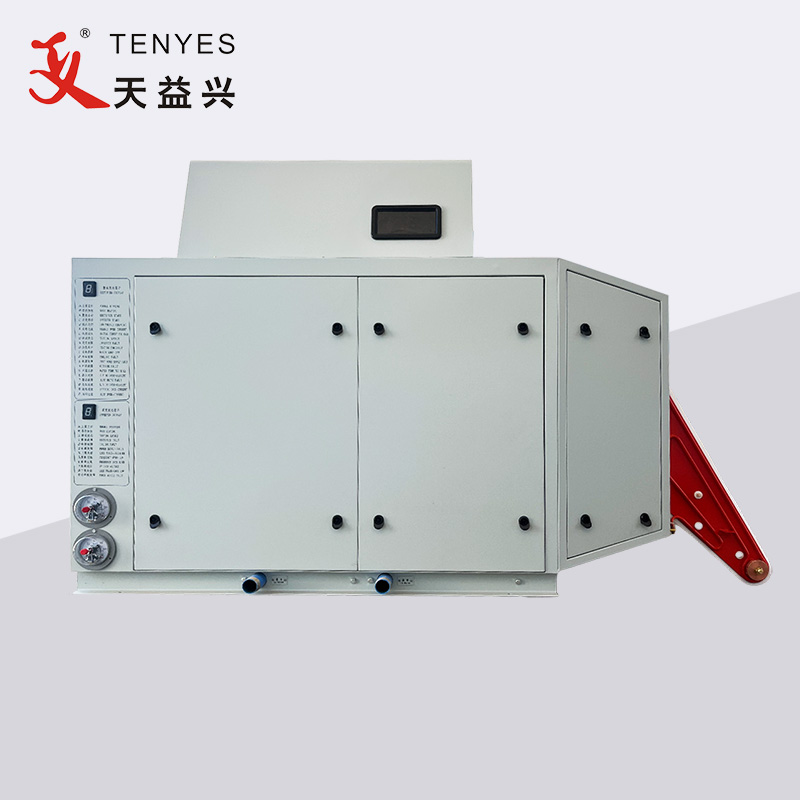

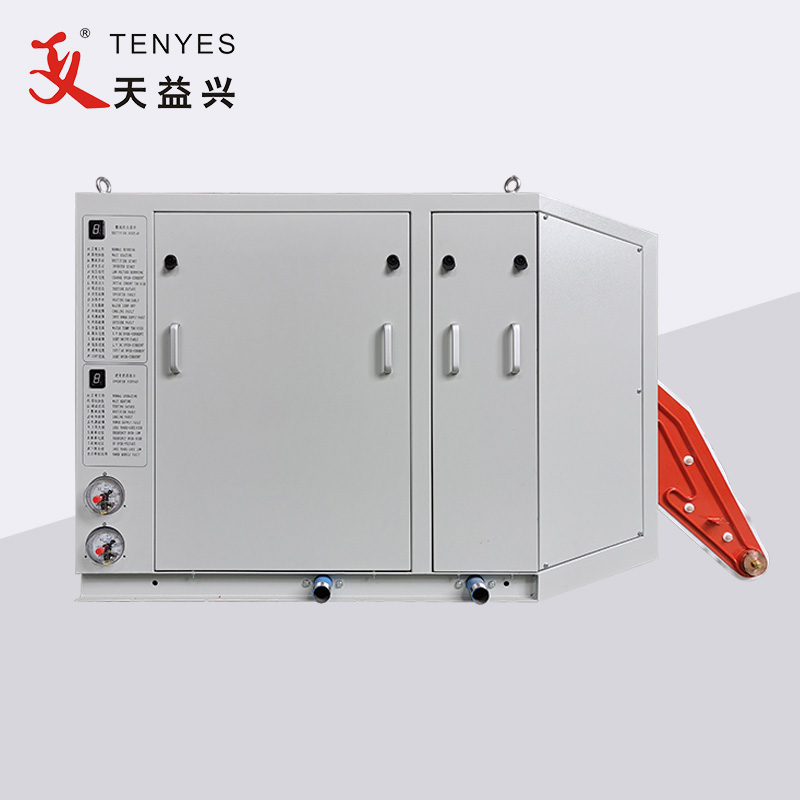

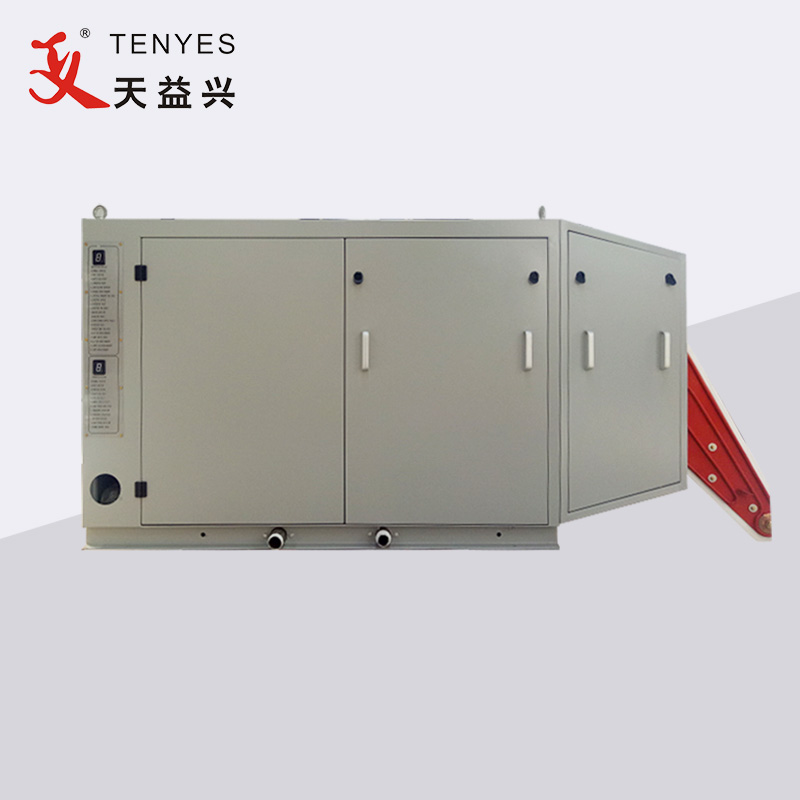

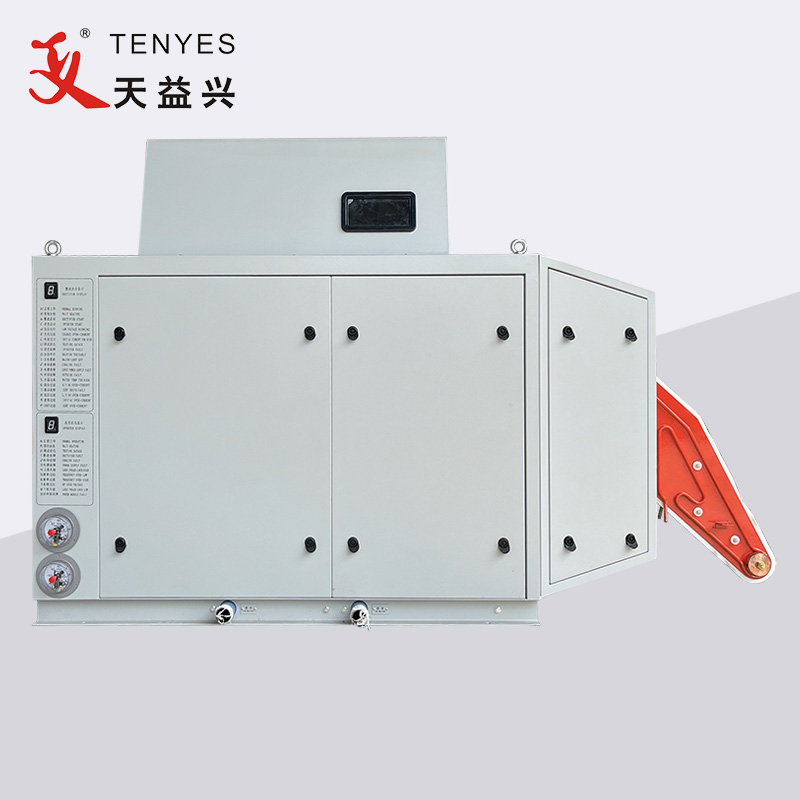

250KW Solid State High Frequency Compact Pipe Welder

TENYES is a reliable manufacturer of pipe welding equipment based in China, offering many selection of Solid State High Frequency Compact Pipe Welder. Among their finest creations is the state-of-the-art 250KW Solid State High Frequency Compact Pipe Welder, which is designed to provide a seamless and reliable welding experience for clients.The 250KW Solid State High Frequency Compact Pipe Welder use a diode uncontrolled rectifier bridge eliminates the need for phase recognition. The three-phase AC power supply inputs (ABC) are freely interchangeable and easy to debug and maintain.

Send Inquiry

Technical Parameters

|

Model |

GGP250-0.3-H |

|

Application |

Welding carbon steel, galvanized steel strip, stainless iron, aluminum and other materials, wall thickness range of 0.5-1.5 mm. Welding (round pipe, square pipe, special-shaped pipe, composite pipe), etc. Welding speed is 60-130 meters per minute. |

|

Rough size |

2435mm*900mm*1800mm (L*W*H) |

|

Welding mode |

induction type |

|

Rated Output power |

250kW |

|

Rated DC voltage |

240V |

|

Rated DC current |

1250A |

|

Rated frequency |

300KHZ |

|

The whole efficiency |

η≥90% |

|

Ripple factor |

<1% |

|

Power distribution capacity |

≥300kVA |

|

Power factor |

≥0.96 |

|

Power supply voltage |

3-phase 380V/50Hz (equipment could work at the voltage 380V±5%) |

Brief introduction and advantages of 250KW Solid State High Frequency Compact Pipe Welder

This compact welder is the latest scientific research achievement of our company's scientific research personnel, and has obtained the national patent (ZL201520767232.X). Its main feature is to replace the original thyristor and iron core rectification with advanced high-power transistor (IGBT) and high-efficiency magnetic core transformer.

Compact welder advantages as following:

High power factor: power factor≥0.96, no need to add reactive power compensation equipment.

Harmonic pollution is small: no additional harmonic processing equipment is required

Smooth output power: small output ripple factor, less burr of welded steel pipe, more uniform weld seam and high finish

Fast protection: fault interlock protection time≤10μs. The equipment is more reliable

High power efficiency: the efficiency of the whole machine is improved because the reactive power loss is reduced

Small size, light weight, simplified wiring, convenient testing and maintenance.

Comparison of compact welder and solid-state high-frequency welder

|

Compact welder |

Solid-state high-frequency welder |

|

High efficiency, and electricity saving by 15%-25% than the solid state welder |

Relatively high-efficiency |

|

Single cabinet design and easy installation |

Separate cabinet design, and many incoming cables between cabinets |

|

High power factor of up to 0.96, and no need of compensation equipment |

Low power factor and need of compensation equipment |

|

Stable output stability and better welded quality |

Relatively good welded quality |

|

Full modular design and easy maintenance |

Semi-modelar design and relatively complicated maintenance |