- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

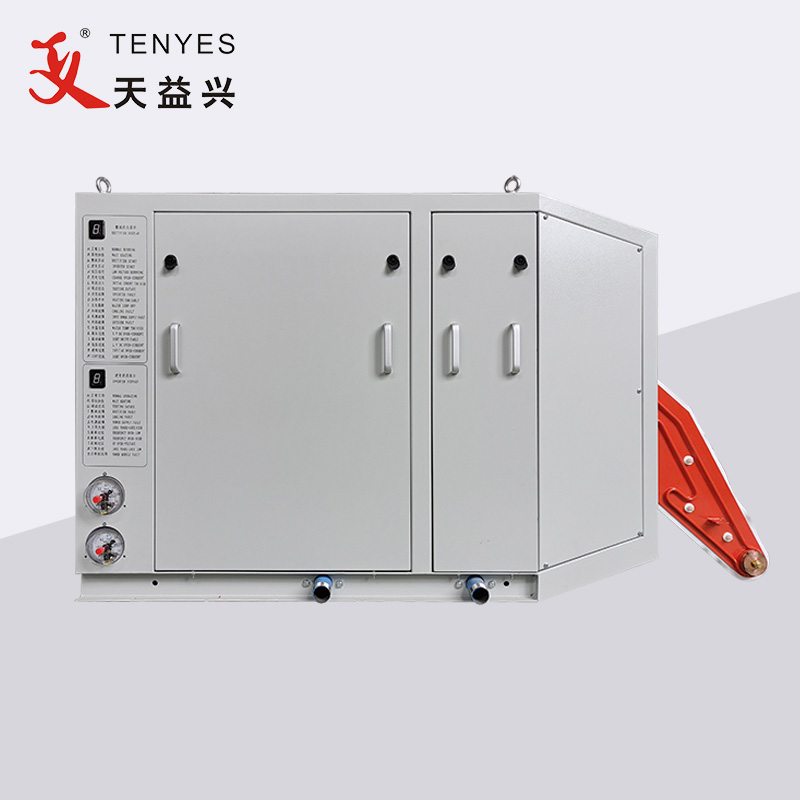

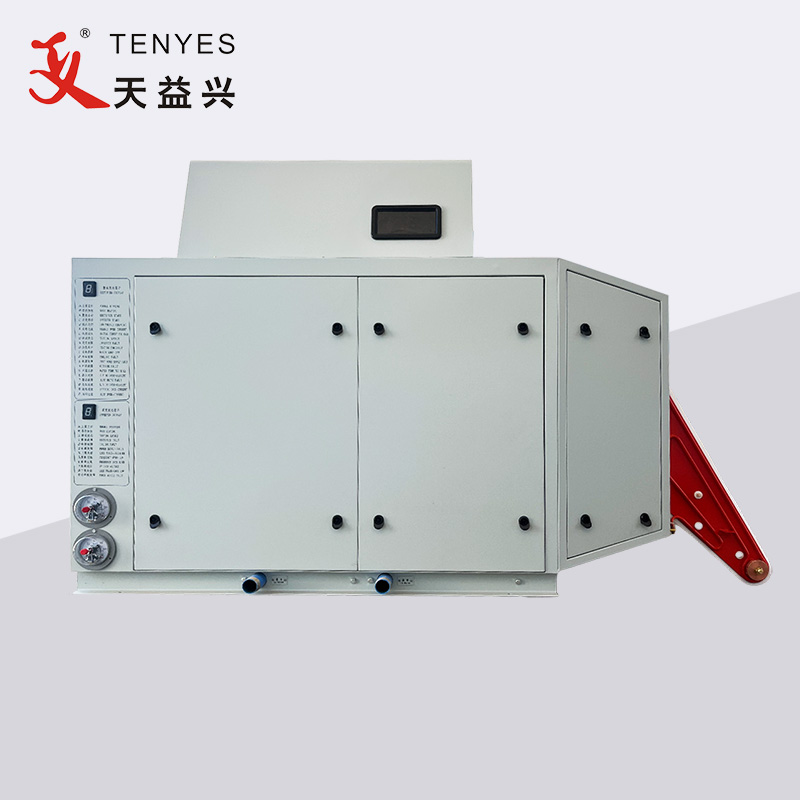

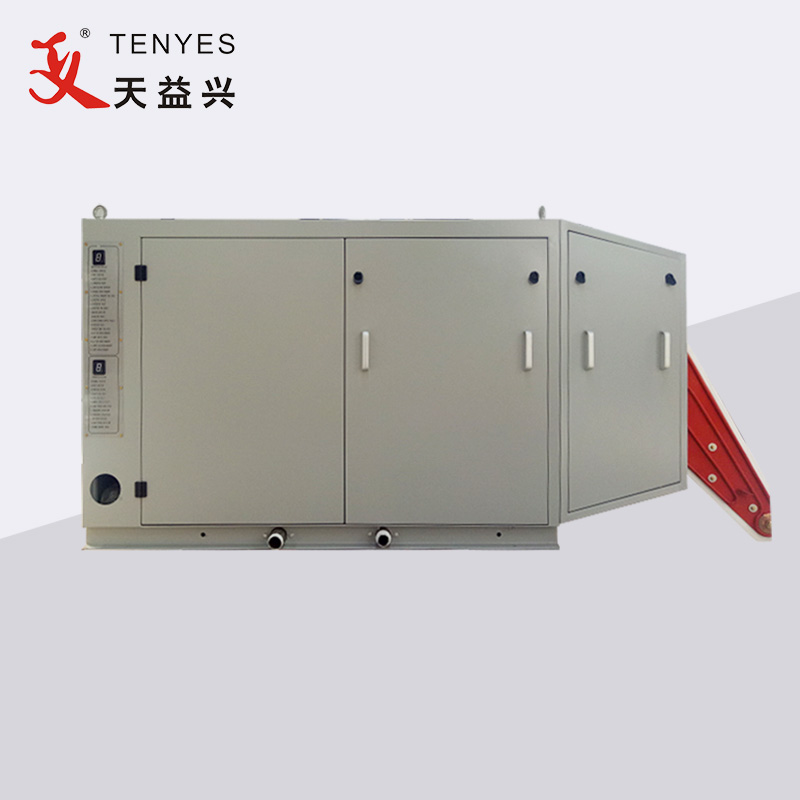

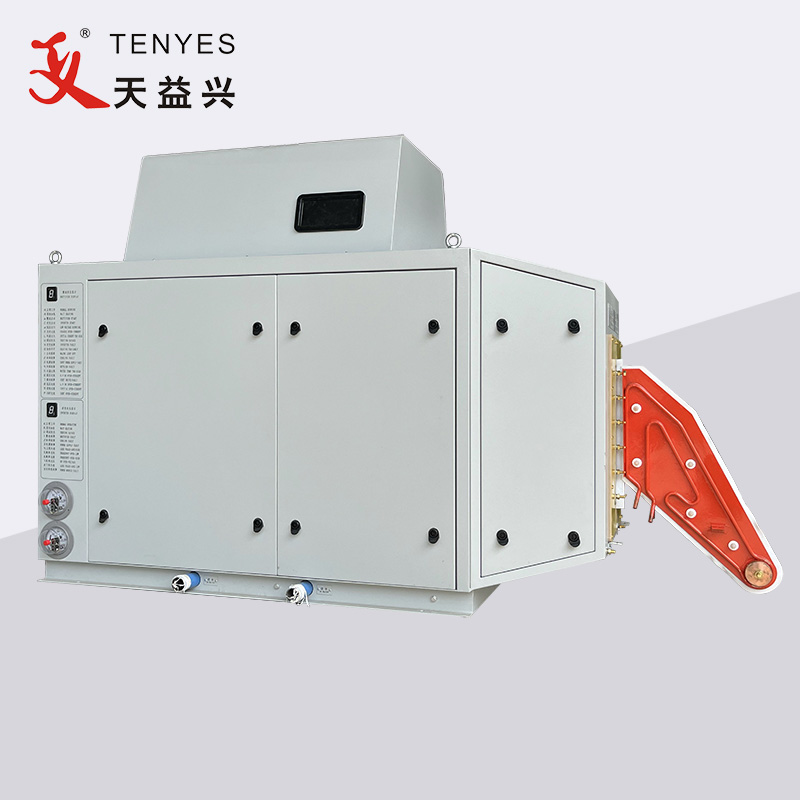

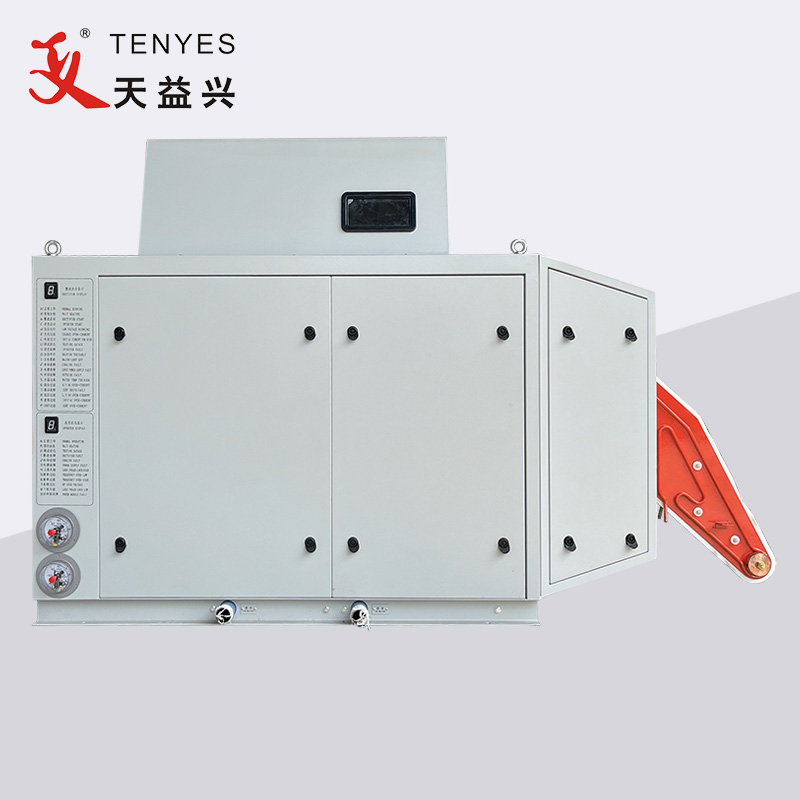

100KW Solid State High Frequency Compact Pipe Welder

TENYES is a China-based company that specializes in producing high-quality solid state high frequency welding equipment, including the 100KW Solid State High Frequency Compact Pipe Welder. As a professional manufacturer and supplier, the company offers a range of products designed to meet the needs of different industrial applications. The 100KW Solid State High Frequency Compact Pipe Welder has compact and lightweight design. By combining the rectifier and inverter sections into a single cabinet, the machine's overall volume is reduced by over 50% compared to conventional high-frequency welder of a similar size. Additionally, its weight is reduced by over 30%, making the machine more portable and space-efficient.

Send Inquiry

Equipment Name: 100KW Solid State High Frequency Compact Pipe Welder

Equipment specifications: GGPY100KW

Components: main cabinet, operation console, cooling system

Equipment use: mainly used for welding ordinary carbon steel, stainless steel, aluminum and other non-ferrous metal pipes.

Features:

1. High power factor: Power factor ≥ 0.95, no additional reactive power compensation equipment is required for this equipment.

2. Energy-saving and high efficiency: Since the conventional high-frequency isolation step-down transformer is removed, the interconnection line is significantly reduced, so the reactive power loss is reduced. Tests have shown that the all-in-one machine saves about 30% compared with conventional solid-state high-frequency.

3. The output power is stable: the output ripple coefficient is small, the welded steel pipe has less burrs, the weld seam is more uniform, the finish is high, and the weld quality is good.

4. Small size, light weight, simplified connection, complete protection, fault chain protection time ≤10us, convenient debugging and maintenance, and more reliable equipment.

Scope of application:

① Steel pipe diameter φ 7- φ 12

② The wall thickness of strip steel is 0.2-1mm

③ Welding method: induction welding

④ Welding speed: 60-130 M/min

Operating parameters:

① Rated power: 100KW

② Rated DC voltage: 250V

③ Rated DC current: 450A

④ Rated frequency: 600KHZ

⑤ Overall efficiency: ≥ 85%

⑥ Output high frequency power: ≥ 100kW

Power supply requirements:

① Power supply form: three-phase four wire power frequency AC, line voltage 380 ± 5%,

② Power supply capacity: more than 100kVA.

③ Power factor: ≥ 0.85

④ Power supply cable: plastic copper wire ≥ 75mm2 per phase, ground wire ≥ 30mm2

100KW Solid State High Frequency Compact Pipe Welder it includes rectifier and inverter.

rectifier part: it is used to change the three-phase 380V AC rectifier into 0-250V adjustable DC current after voltage regulation, so as to meet the needs of the later inverter unit. Built in three-phase rectifier bridge, charging capacitor, IGBT bridge, smoothing reactor, filter device, control and protection circuit and display instrument.

Characteristics of rectifier control circuit: it is controlled by single chip microcomputer (mcs89c51) and large-scale digital integrated circuit, with high control precision, rapid response and clear state display.

Software protection mode: high over-current (9), low over-current (8), external fault (4), incoming power supply fault (phase loss, over-voltage, under-voltage, serious imbalance of three-phase voltage, display 3), cooling water fault (2), inappropriate voltage and current ratio (L), inverter fault (Y).

Hardware protection: main switch off protection, resistance capacitance absorption, resistance protection (lightning protection), fast melting protection.

inverter part: invert the 0-250 DC current sent by the rectifier cabinet into a high-frequency current of hundreds of kHz to meet the needs of welded pipes.

The inverter cabinet is composed of the following parts: power unit, channel capacitor, leakage reactance, control circuit, cooling air conditioner, etc.