- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

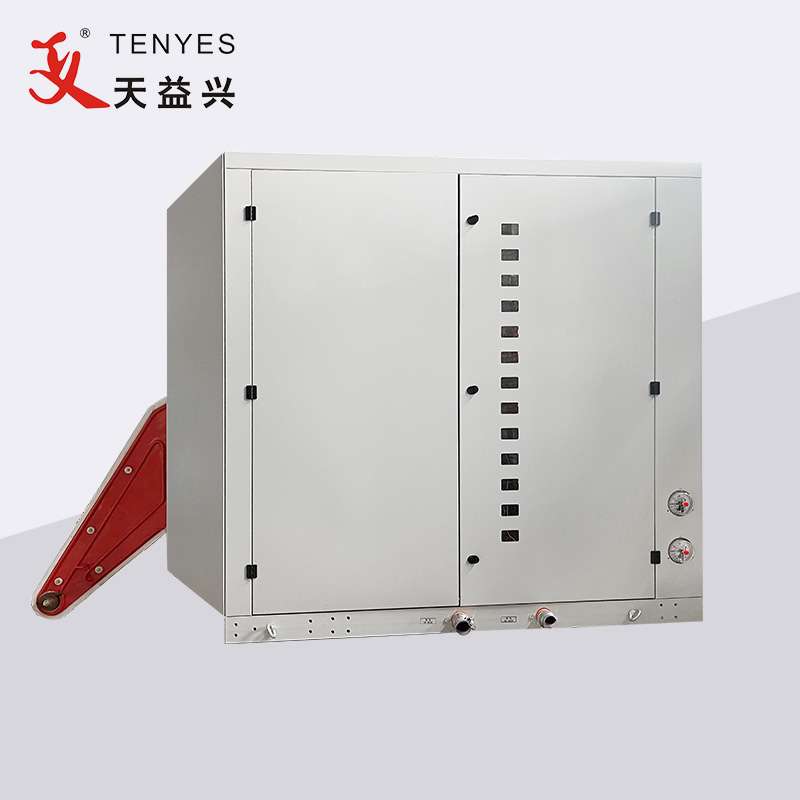

300KW High Frequency Pipe Welding Machine

TENYES 300KW High frequency pipe welding machine is designed for straight seam induction welding of steel pipe/tube. The whole set of welder comprises of rectifying cabinet, inverter cabinet (slot cabinet), circulating cooling system for soft water, step-down transformer, center control console, output bus bar, induction/contact welding system, and so on. The solid-state high frequency welder is designed according to continuous operations. And the instructor are three turns or single turn.

Send Inquiry

The single layer power module output power is more than 60KW, adopting 3 layers power module (contrast to 150KW) in parallel to the whole machine. The rated working frequency is 350 KHz. The maximum output power of the entire machine can reach 180 KW. The same power modules have interchangeability.

Main Technical parameters of 300KW High Frequency Pipe Welding Machine:

1.Application:

①Steel pipe diameter: φ42-φ90

②Thickness: 1.6-3.2

③Welding mode: induction type

④Welding speed: 40-100mpm

2.Operating parameter:

①Rated output power: 300KW

②Rated DC voltage: 240V

③Rated DC current: 1500A

④Rated frequency: 300KHZ

⑤The whole efficiency: ≥85%

⑥output high frequency power: ≥300KW

3.Power supply:

①Power supply distribution: 380±5% (3-phase 4-line AC, line voltage380±5%)

②Power distribution capacity: ≥360KVA

③Power factor: ≥0.85

④Power supply cable: each phase of plastic-covered copper cable ≥300mm², ground wire≥150mm2