- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

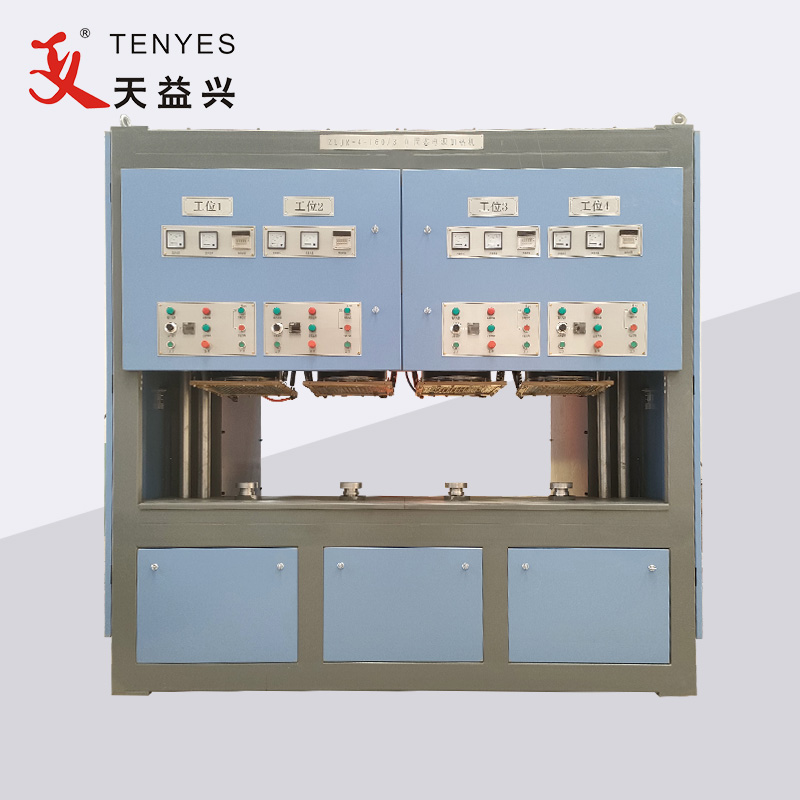

200KW Straight Cookware Bottom Heating Machine

TENYES 200KW Straight Cookware Bottom Heating Machine has a range of advantageous features, including energy efficiency, superior heating quality, rapid heating speed, and digital display functionality that simplifies operation and maintenance tasks. It is suitable for diverse industrial applications, including gear, gear ring, and shaft induction quenching. One of the primary features of this equipment is its IGBT super-audio power source, which offers energy-efficient and reliable performance, making it cost-effective and safe to use. The equipment also ensures uniform heating, guaranteeing excellent product quality and consistency.

Send Inquiry

This 200KW Straight Cookware Bottom Heating Machine mainly consists of three parts: Heating power source, Heating machine and Water cooling system.

This 200KW Straight Cookware Bottom Heating Machine is mainly used for stainless steel pan, pot, kettle and aluminum, copper, carbon steel etc. utensils pre-heating before compound base pressure welding. Our heating power source and heating machine are controlled by microcomputer, and it is an electric, mechanical and pneumatic integrated high-tech equipment controlled by several sets microcomputer. This equipment using IGBT super-audio frequency power source to heat, and the heating temperature more uniform than SCR medium frequency, and the production speed more faster, high efficiency, stable and reliable quality, the main performance of our machine is in the domestic leading level and earn wide recognition among the users.

Heating power source:

1)Main technical parameters and performance:

Incoming power supply: three-phase 380V±20V, 50HZ±1HZ.

Rectification method: three phase full controlled bridge rectifier.

Rated power: 200KW (4 position)

Control loop: rectifying part, inverter part,single chip microcomputer (MC89C51) and digital integrated circuit.

Start mode: sweep frequency zero voltage start.

Protection mode:

over-current protection

over-voltage protection

burnt out protection

Inlet wire resistance capacity absorption, resistance protection

Lack phase protection

Cooling water temperature and water pressure flow detection and alarm, etc.

2)Features:

The overall structure design of power source is reasonable, the technology is mature and stable, energy-save and electricity-save. Adopt microcomputer control, high integration and excellent performance. Digital display working state, easy to operate and easy to troubleshoot. The main components are imported and others use the domestic famous brand-name components, the failure rate is very low.

Heating machine

1)Main technical parameters and performance:

heated cookware compound bottom diameter: 70mm to 300mm (if users have special requirements, the maximum heated diameter can up to 500mm).

Working position: four working position

Maximum height of working zone: 350mm, that is, the height of heated cookware compound base pan or pot is no more than 350mm (if users have special requirements, the maximum height can up to 550mm).

Cooling water pressure for heating head: 0.5MPa<P<0.6Mpa,sensor water flow rate not less than 90 liters/min

working time: 4-12 pieces per minute (depending on the work-piece thickness, diameter, working position)

Inlet air pressure: 0.5MPa < P < 6MPa

heating mode: manual/semi-automatic, under the semi-automatic mode the heating time is given to complete.

Heated material: stainless steel, aluminum, copper, steel and their com plexus

2)Features:

The machine has small size, and the overall structural design is reasonable, flexible, convenient workshop layout, greatly improve product output.

Heating machine

1)Main technical parameters and performance:

a.internal water: the use of pure water

b.The fan make the internal water cooling and with external water spray cooling

c.protection: both internal and external water have water pressure, water temperature, water flow and water level protection alarm indicator lights.

2)Features:

a.water saving: water consumption is 40% to 50% of water cooled condenser.

b.power saving: fans and pumps power consumption is about 70 - 80% of the compressor power consumption

c.system adopts soft water closed cycle, no scaling, not to block pipelines, good heat exchange effect.

d.air cooling, spray cooling meet the cooling requirements, thus ensure the key parts will not be damaged due to overheating, extend the service life of the equipment.