- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

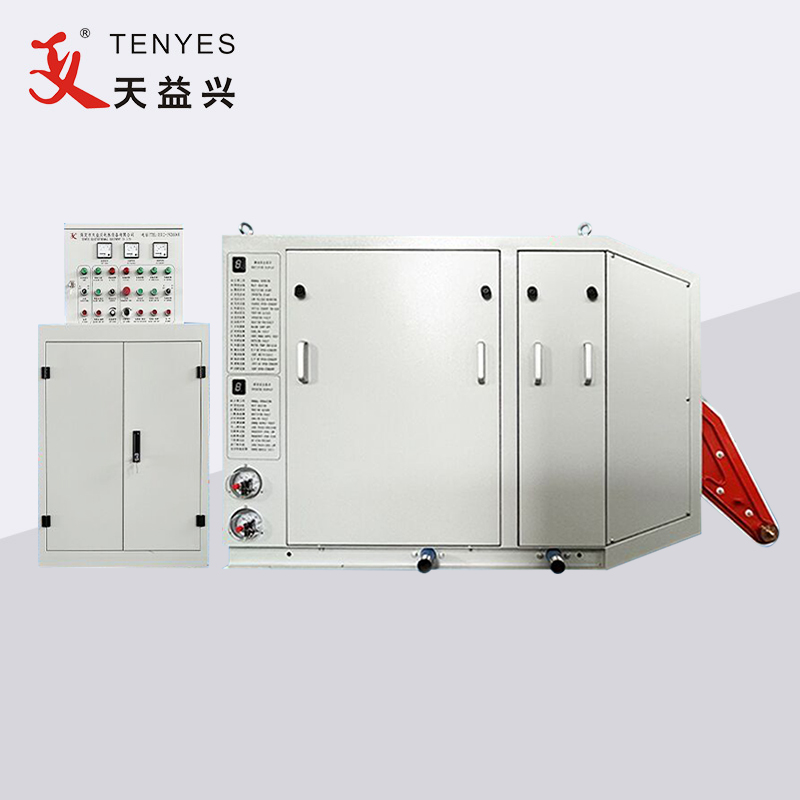

SiC-MOSFET Solid State High Frequency Pipe Welder

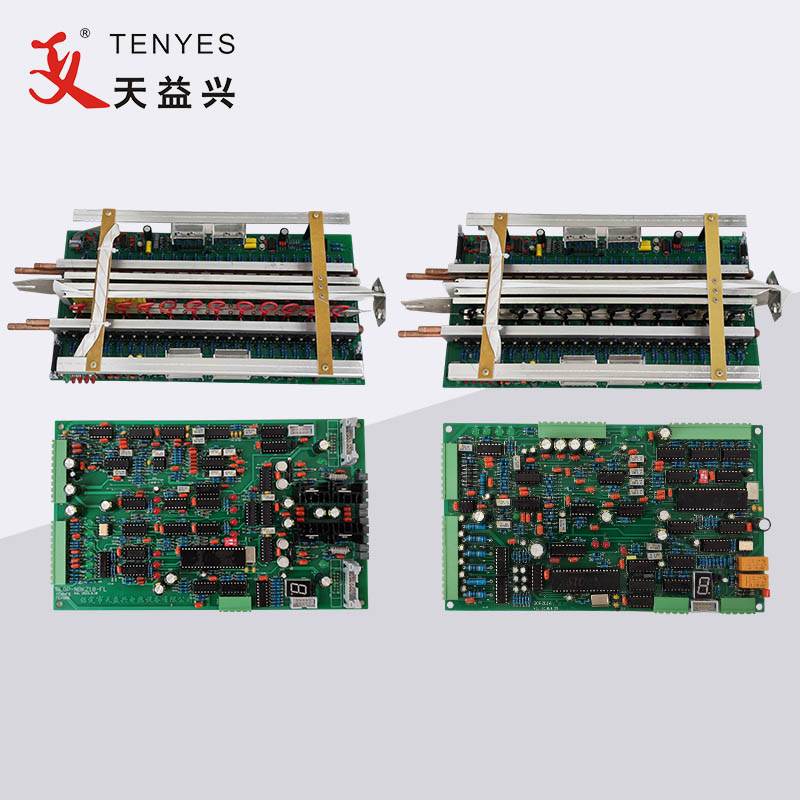

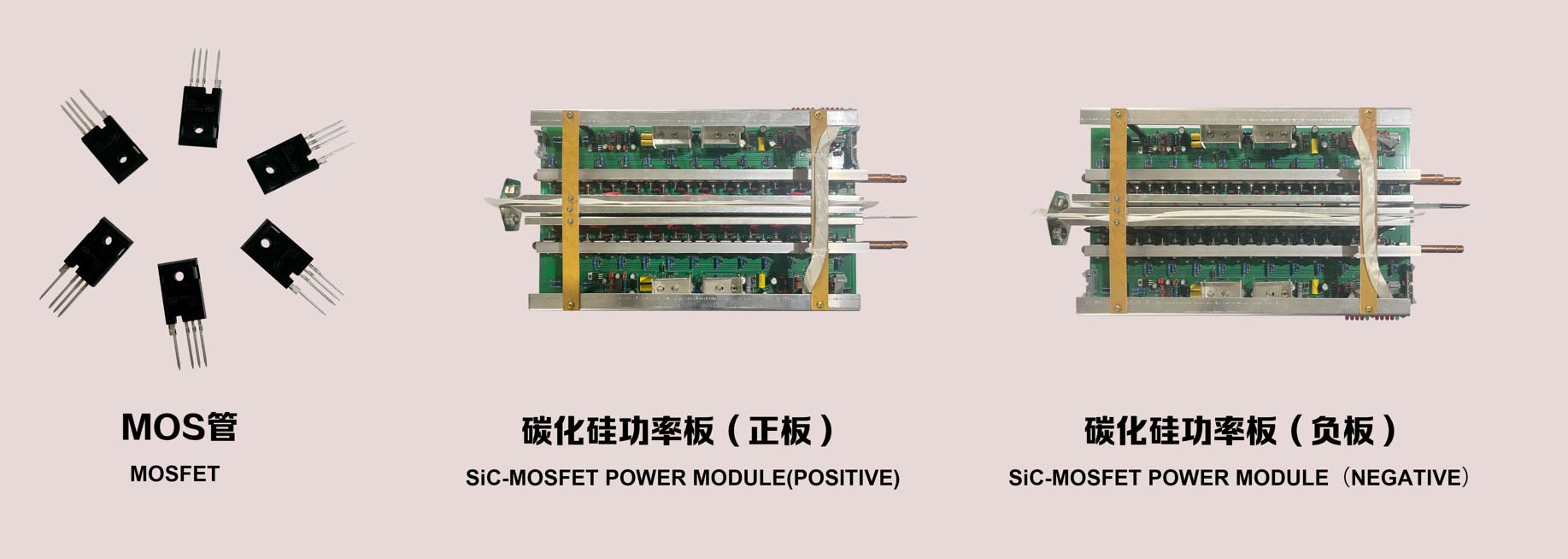

SiC-MOSFET Solid State High Frequency Pipe Welder adopts third generation semiconductor materials to instead of low-voltage normal mosfet tube.SiC mosfet have High temperature and high pressure resistance.SiC mosfet mainly used on the power module boards.This kind of power boards used in the solid state high frequency pipe welder.

Send Inquiry

As the technology improved, recently for the solid state high frequency welder adopts third generation semiconductor material called SiC-MOSFET.

The Third Generation Semiconductor Materials SiC-MOSFET Performance Characteristics

1. High temperature and high pressure resistance: SiC has a wide band gap about 3 times that of Si, so it can realize power devices that can operate stably even under high temperature conditions. The insulation breakdown field strength of SiC is 10 times that of Si, so it is possible to fabricate high-voltage power devices with a higher doping concentration and a thinner film thickness drift layer compared to Si devices.

2. Device miniaturization and lightweight: Silicon carbide devices have higher thermal conductivity and power density, which can simplify the heat dissipation system, so as to achieve device miniaturization and lightweight.

3. Low loss and high frequency: The working frequency of silicon carbide devices can reach 10 times that of silicon-based devices, and the efficiency does not decrease with the increase of working frequency, which can reduce the energy loss by nearly 50%; At the same time, due to the increase of frequency, the volume of peripheral components such as inductance and transformers is reduced, and the volume and other components cost after the composition of the system are reduced.

SiC-MOSFET Solid State High Frequency Pipe Welder Advantages

1.60% lower loss than Si-MOSFET devices,welder inverter efficiency increases more than 10%,welding efficiency increases more than 5%.

2.Single SiC-MOSFET power density is large,assembled quantity is reduced accordingly,which directly reduces fault points and external electromagnetic radiation,and improves the reliability of the inverter power unit.

3.SiC-MOSFET withstand voltage higher than original Si-MOSFET, welder DC rated voltage has been increased accordingly under the premise of ensuring safety(280VDC for parallel resonant welder and 500VDC for series resonant welder).Power factor of the grid side ≥ 0.94.

4.New SiC-MOSFET device loss is only 40% of Si-MOSFET, under certain cooling conditions,switching frequency can be higher,series resonant Si-MOSFET welder adopts frequency doubling technology, adopts SiC-MOSFET can directly design and manufacture up to 600KHz high frequency welder.

5.New SiC-MOSFET welder DC voltage increases, grid side power factor high,AC current small,harmonic current small,customer’s cost of power supply and distribution is greatly reduced,and the power supply efficiency is effectively improved.