- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

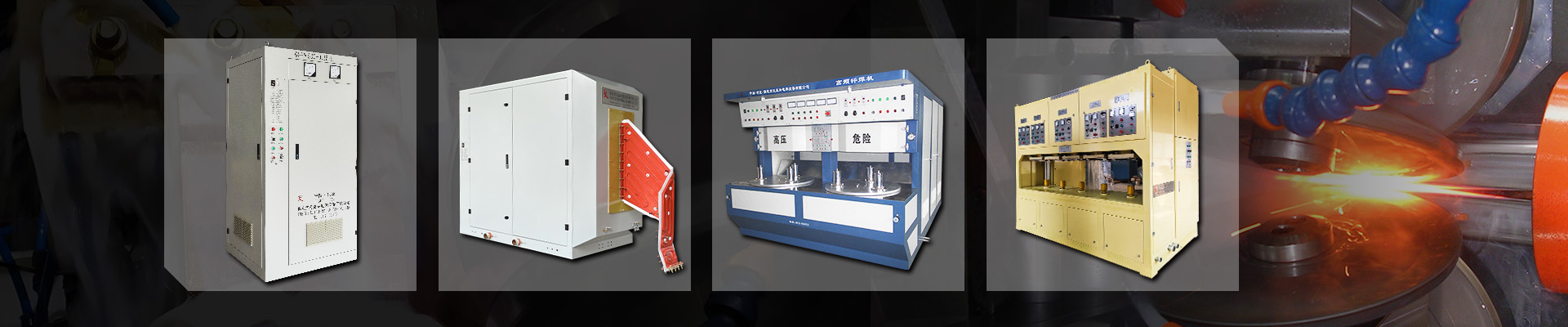

The feature of High Frequency Pipe Welding Machine

2025-04-27

Here’s a simple breakdown of the features of a High Frequency (HF) Pipe Welding Machine:

Key Features:

High Welding Speed

HF welding machines can weld pipes at much higher speeds compared to traditional methods — perfect for mass production.

Strong, Consistent Welds

The high-frequency current ensures deep, uniform heat penetration, making strong and reliable weld seams.

Energy Efficient

Only the edges of the pipe are heated (not the whole pipe), so the process uses much less energy.

Suitable for Various Materials

Works well with carbon steel, stainless steel, aluminum, and even some non-ferrous metals.

Precision Control

Modern HF welding systems offer fine control over frequency, power, and temperature, improving welding quality.

Automatic Operation

Most machines are highly automated, which reduces manual work, ensures consistent output, and improves safety.

Minimal Heat Affected Zone (HAZ)

HF welding localizes the heating, reducing distortion and preserving the mechanical properties of the pipe material.

Compact Design

Many HF pipe welding lines are designed to be space-efficient, fitting into tighter production areas.

Customization Options

Machines can be customized for different pipe diameters, thicknesses, and material types.

Integration with Inline Testing

Often integrated with non-destructive testing (NDT) tools like ultrasonic or eddy current testers to inspect weld quality instantly.

Tenyes Electrothermal Equipment Co., Ltd. (former Baoding Tianyi Electrothermal Technology Institute) founded in 1999, and restructured into a company system in 2002. We are a private high-tech enterprise that integrates research and development, production, and technical services. We specialize in producing high and medium frequency induction heating power supplies and supporting equipment, mainly serving the fields of steel pipe manufacturing and metal heat treatment. If you are interested in our products or have any questions, please feel free to contact us.